Five Advantages of Aluminum Anodizing Manufacturers' Products Introduction

1. Bottom layer for spray painting and electroplating.

2. Prevention of product corrosion.

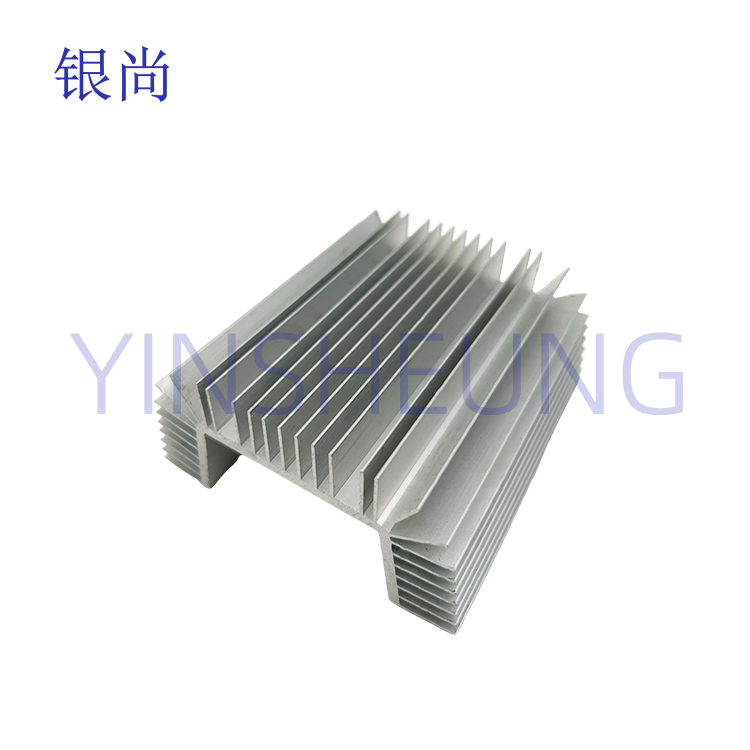

3. Protection and decoration.

4. As a hard wear-resistant layer.

5. As an insulation layer for electricity:.

The traditional surface pre-treatment process for aluminum profiles with sand surface is to use chemical sand surface method, which uses alkali etching to form a sand surface on its surface. However, this is an unreasonable process with high aluminum consumption, alkali consumption, and acid consumption.

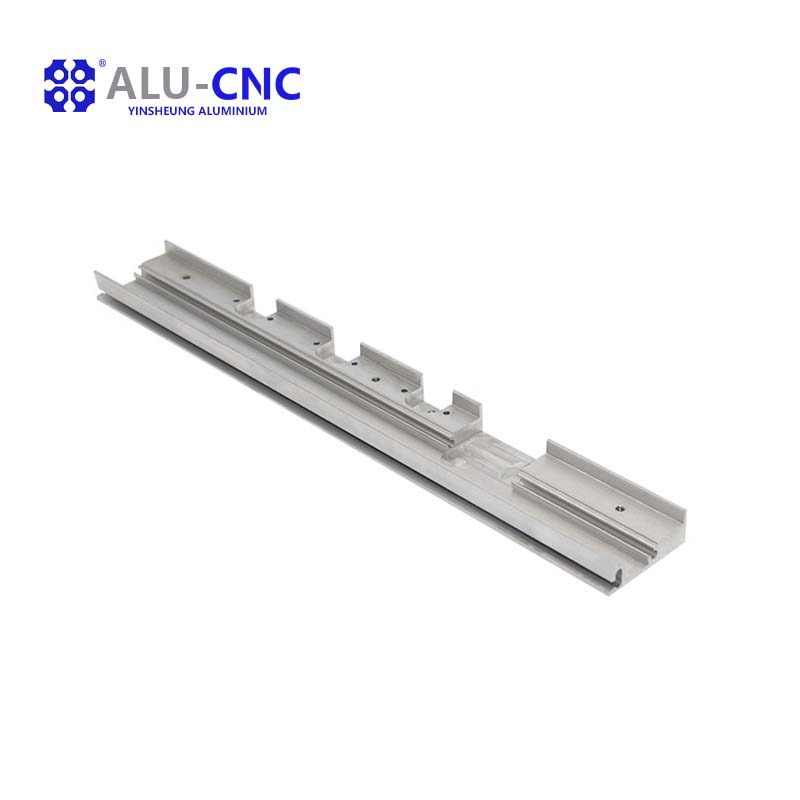

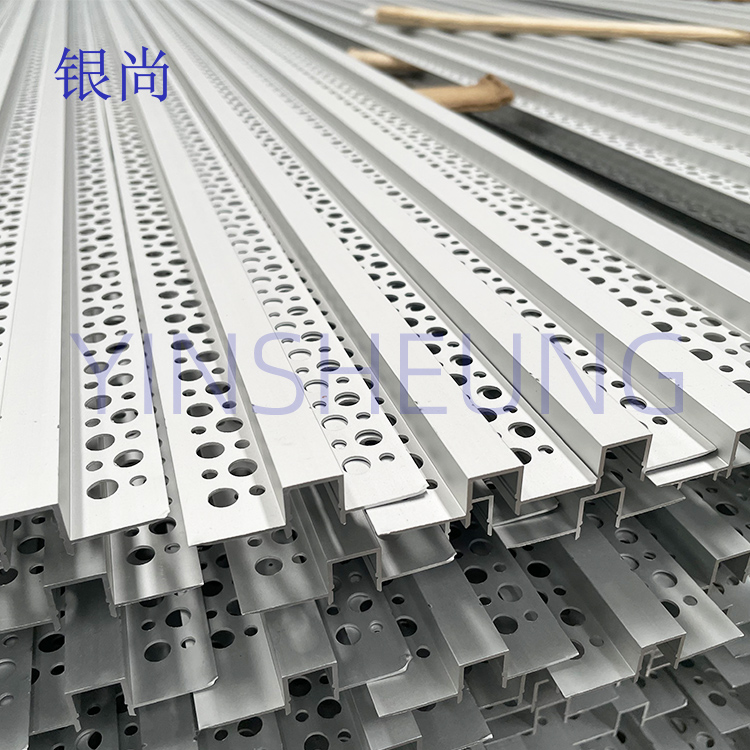

Industrial aluminum alloy profiles are a common consumable in automated production. Due to their excellent physical properties, they are widely used in industrial automation and have become materials for customized equipment frame brackets and safety fences.

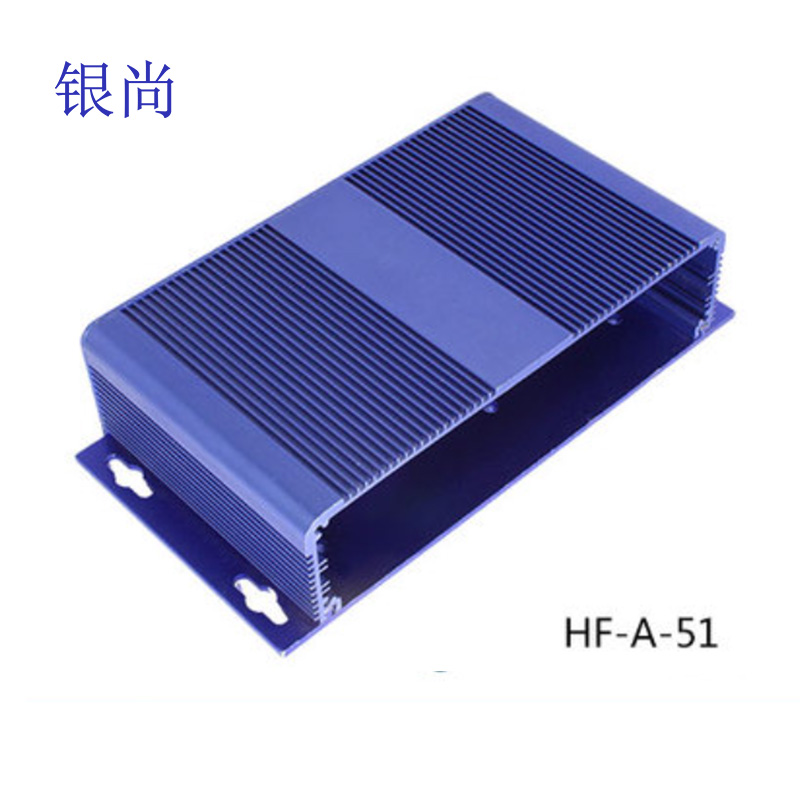

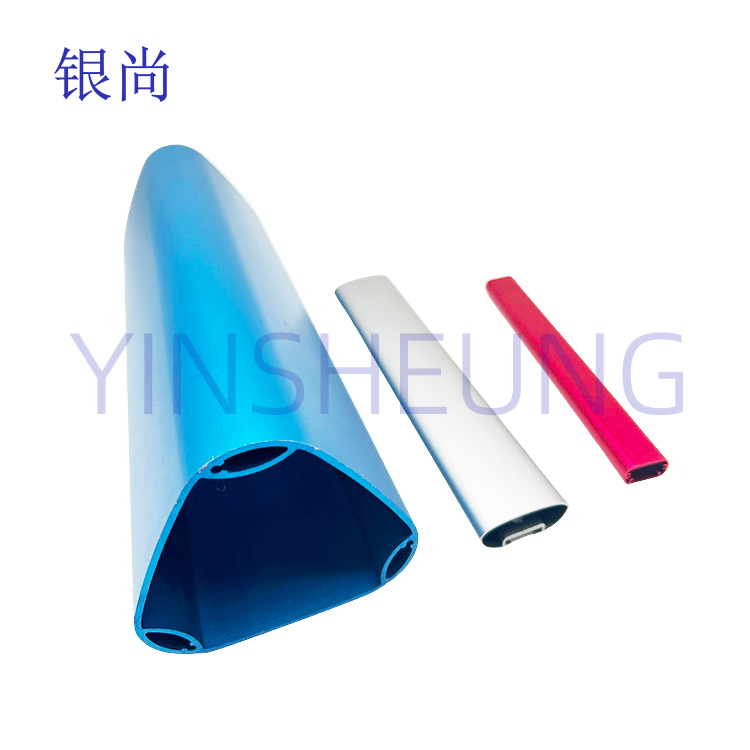

Surface treatment and coloring of aluminum alloy to make it look beautiful and elegant, improve its wear and corrosion resistance, make it more durable, and meet the application of aluminum alloy in modern social decoration.

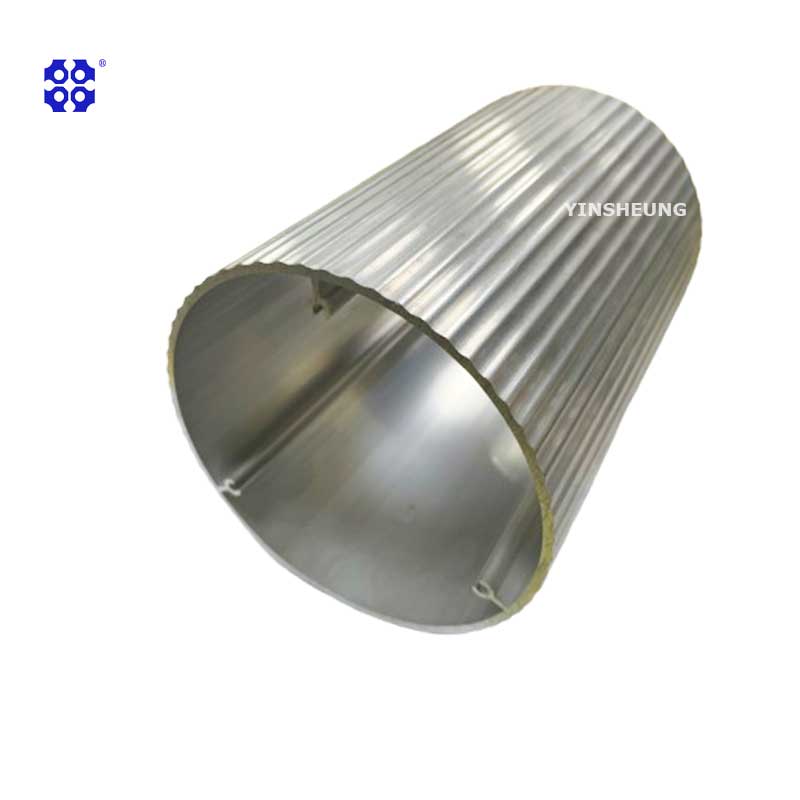

Industrial aluminum profiles are an alloy material mainly composed of aluminum. Aluminum rods are melted and extruded to obtain aluminum materials with different cross-sectional shapes. However, the proportion of added alloys varies, resulting in different mechanical properties and application fields of industrial aluminum profiles produced.

Aluminum alloy is the most widely used non-ferrous metal structural material in industry, and has been widely used in aviation, aerospace, automotive, mechanical manufacturing, shipbuilding, and chemical industries.

Pure aluminum is divided into smelting products and pressure processed products. The former is represented by Chemical composition Al, and the latter is represented by Pinyin LV (aluminum, industrial). Aluminum alloys can be divided into two categories according to processing methods: deformed aluminum alloys and cast

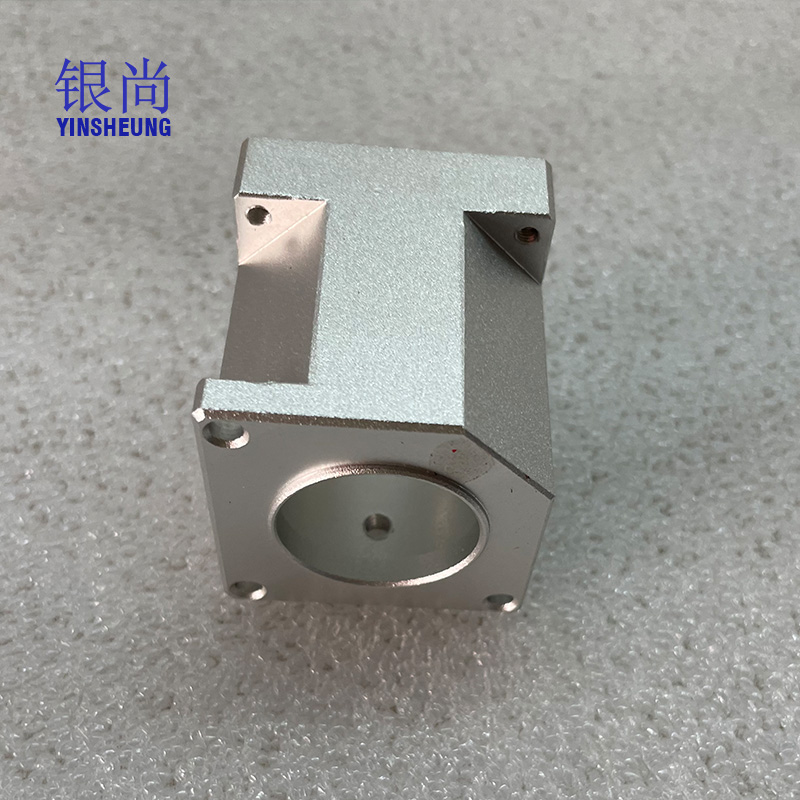

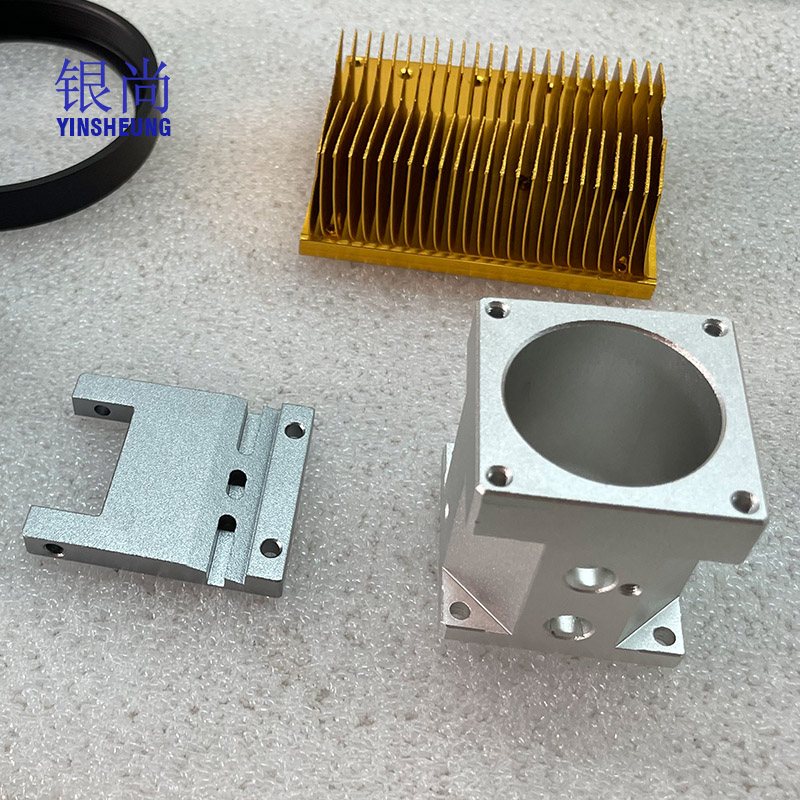

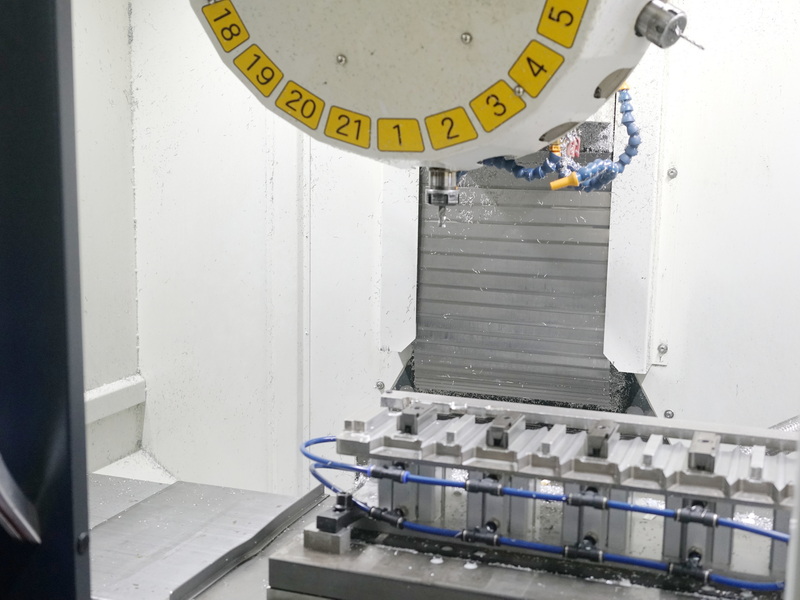

CNC machining stands for computer numerical control and basically means that a machine is controlled by a set of commands from a controller.

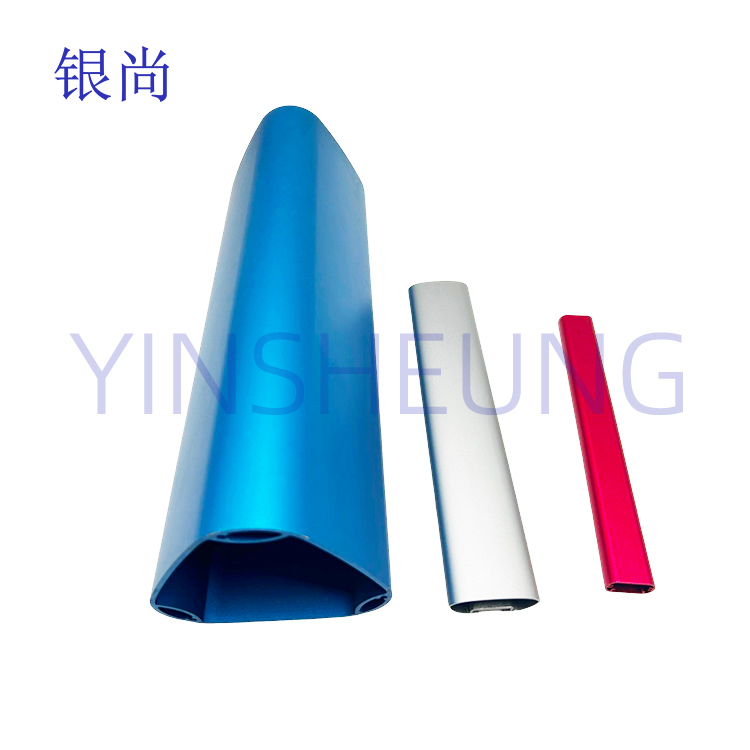

The processing technology for different colors of industrial aluminum profiles is certainly different, and the surface color of industrial aluminum profiles is obtained through different processing and surface treatment processes. The common technical processes on the market are anodizing treatment, electrophoresis treatment, spray surface treatment, and nano treatment. Not all of these processes can produce the desired colors. Each process has its own representative color. Below is a brief introduction.

Aluminum surface anodizing treatment