Focusing on the development of the entire aluminum profile processing industry chain, promoting the overall improvement of industry technology progress and management level, promoting industry technology exchange and international cooperation, guiding industry technology innovation, promoting energy conservation and emission reduction, and promoting the improvement of industry technology standardization level.

Foshan Nanhai, Guangdong is an early aluminum processing cluster in China, which has contributed excellent aluminum profiles to the glory of China's construction industry. 70% of the aluminum profiles used for curtain walls of high-rise buildings over 400 meters worldwide are manufactured in Nanhai.

In recent years, due to the convergence of global economic vitality and slow growth rate, Foshan Nanhai aluminum processing industry chain enterprises, which are at the forefront of the aluminum profile market, have felt the complex and uncertain coolness of this market. Although the coolness is striking, we Foshan aluminum processing enterprises fully feel that our annual consumption of aluminum profiles is basically large, and the potential for aluminum to replace other materials is enormous, so the vitality potential of the aluminum processing market is still good. As long as efforts are continuous, innovation is continuous, confidence is constant, and market uncertainty is regarded as a norm, then the market is not a bad industry, only a bad enterprise.

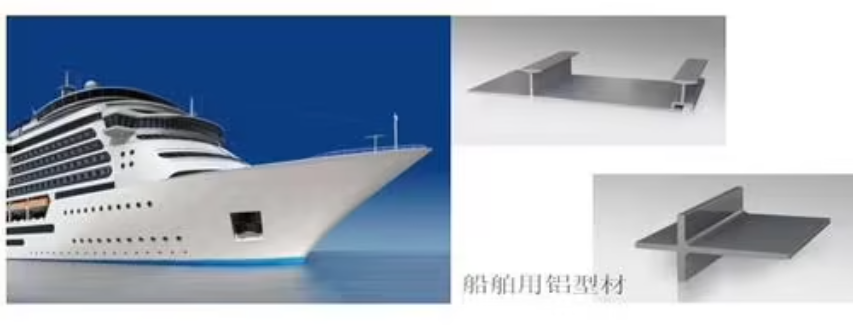

In recent years, China's strong attitude towards the South China Sea issue means that in the future, China will carry out more economic and even military actions to safeguard its own interests in the South China Sea. To carry out activities at sea, ships are only essential. Undoubtedly, more ships will be launched in the future, traveling at the southern end of China, and the demand for industrial aluminum hull materials will also become quite strong.

【Aluminium Knowledge】Classification, grades, uses, naming, and processing techniques of commonly used aluminum alloys

1. Classification of aluminum alloys

2. Material categories of aluminum alloys

According to the Financial Times, Toyota announced a new breakthrough on July 4th, stating that it is about to halve the size, weight, and cost of electric vehicle batteries. Just half a month ago, Solid-state battery technology was broken through by Toyota, and the "10 minute charging and 1500 km endurance" was realized.

In fact, since the rise of new energy vehicles, Toyota has been a pioneer in opposing electrification. The slogan is loudly shouted, but the actions are honest. The successive official announcements of the two breakthroughs made by the Japanese media excitedly declared that it is very close to surpass China's new energy!

Aluminum alloy industry chain and its market demand

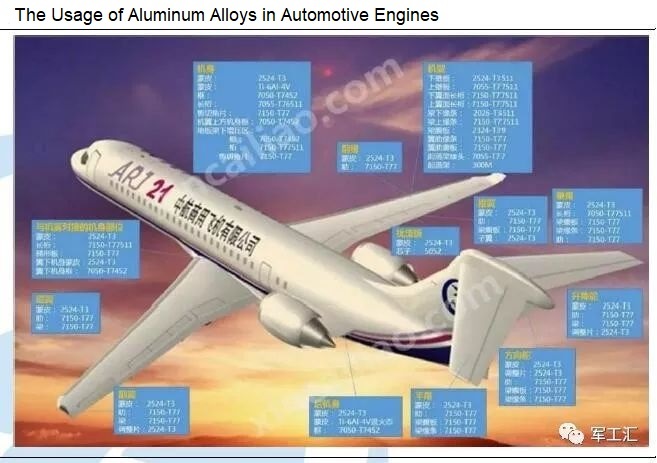

Aluminum alloy has the characteristics of low density, high strength, good corrosion resistance, and excellent processing performance, making it the most widely used metal structural material in the current military industry. In the fields of aviation, aerospace, and naval vessels that pursue lightweight equipment, high-performance aluminum alloys are essential and important lightweight structural materials.

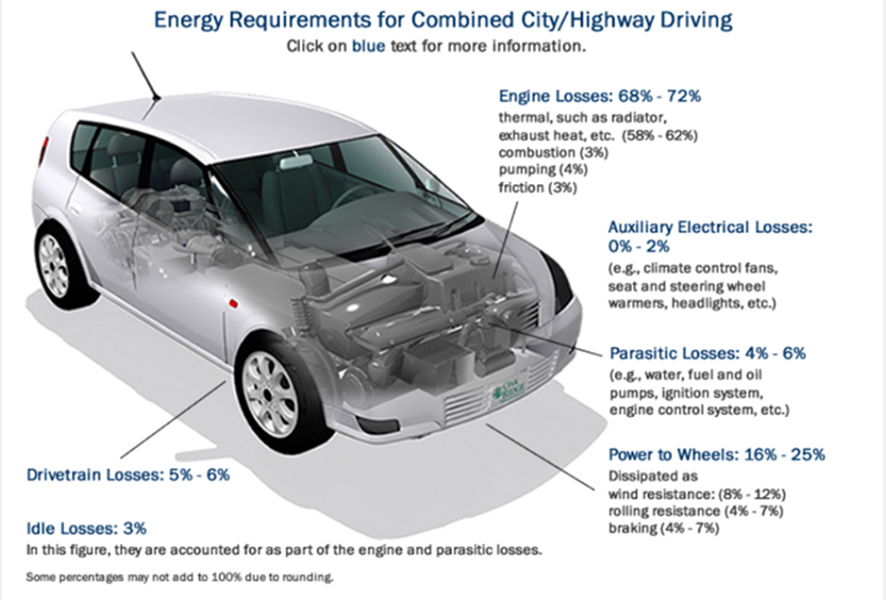

Automotive machining electric vehicles are more environmentally friendly than gasoline driven vehicles, not only because gasoline driven Car dependency rely on fossil fuels, but also because they are more efficient.

The outbreak of new energy cannot be separated from the support of aluminum materials, and the sales of new energy vehicles have reached a new high this year! According to statistics, China's production and sales of new energy vehicles have reached 2.566 million and 2.542 million respectively, a year-on-year increase of 1.8 times. By 2025, China's new energy vehicles will account for 35% of total vehicle sales, and the new energy vehicle processing industry will enter a golden period of development.

Metamaterial -- from engineering materials to engineering materials

As one of the frontier directions in the field of materials science, Metamaterial have experienced vigorous development in the past 20 years. Today, Metamaterial have expanded to include Electromagnetism, a large class of artificial material systems with extraordinary and high performance covering many fields such as optics, mechanics, heat and acoustics.

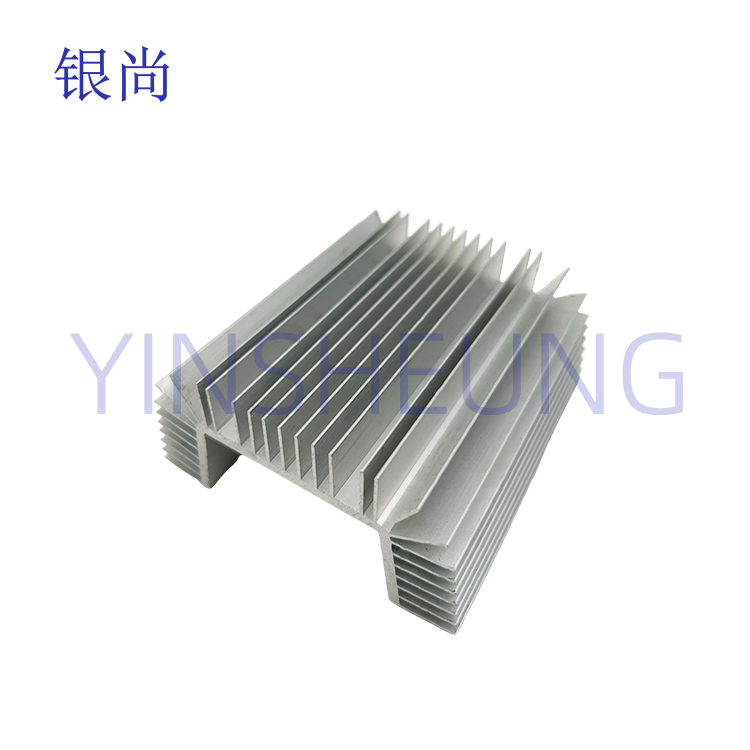

Aluminum profiles for heat dissipation fins

1. Quality requirements for ingots

2. Requirements for molds

3. Reduce squeezing force

4. Extrusion process