Industry Alliance Enters Aluminum Processing Enterprises, Boosting the Development of Enterprises!

Yinshueng CNC Machining Published in Foshan, on August 7, 2023

Topic

#DaliAluminumMaterials

#aluminumprocessing

#industry

Aluminum profile processing

Focusing on the development of the entire aluminum profile processing industry chain, promoting the overall improvement of industry technology progress and management level, promoting industry technology exchange and international cooperation, guiding industry technology innovation, promoting energy conservation and emission reduction, and promoting the improvement of industry technology standardization level.

Foshan Nanhai, Guangdong is an early aluminum processing cluster in China, which has contributed excellent aluminum profiles to the glory of China's construction industry. 70% of the aluminum profiles used for curtain walls of high-rise buildings over 400 meters worldwide are manufactured in Nanhai.

In recent years, due to the convergence of global economic vitality and slow growth rate, Foshan Nanhai aluminum processing industry chain enterprises, which are at the forefront of the aluminum profile market, have felt the complex and uncertain coolness of this market. Although the coolness is striking, we Foshan aluminum processing enterprises fully feel that our annual consumption of aluminum profiles is basically large, and the potential for aluminum to replace other materials is enormous, so the vitality potential of the aluminum processing market is still good. As long as efforts are continuous, innovation is continuous, confidence is constant, and market uncertainty is regarded as a norm, then the market is not a bad industry, only a bad enterprise.

From 2nd to 4th to August, the Guangdong Aluminum Processing Industry Alliance and its delegation once again went deep into aluminum processing enterprises, discussing, understanding, and promoting the development of 31 private economy, continuing to provide impetus for the development of enterprises. Lu Jiyan, Executive Vice Chairman of the Industrial Alliance and Director of the Technical Expert Committee, and his delegation respectively

Ms. Josephine, Chairman of Foshan Yinshang Aluminum Industry Co., Ltd

Mr. Zhong, Chairman of Guangdong Gangxin Aluminum Industry Co., Ltd

Pradi Machinery Manufacturing Co., Ltd

Li Jian, Chairman of Foshan Jiling Electrical Equipment Co., Ltd

Foshan Lianyi Mold Manufacturing Co., Ltd

Conducting a symposium to understand the current market operation status of enterprises, as well as the technological innovation and transformation status of enterprises. Deeply feeling the difficulties and unremitting pursuit and efforts of small and medium-sized private enterprises, taking the path of specialization, refinement, and innovation has become a consensus among these small and medium-sized entrepreneurs. Only by taking the path of specialization, refinement, and innovation can small and medium-sized enterprises grow healthily.

↓↓↓↓

1

Visiting Yinsheung Aluminum Industry

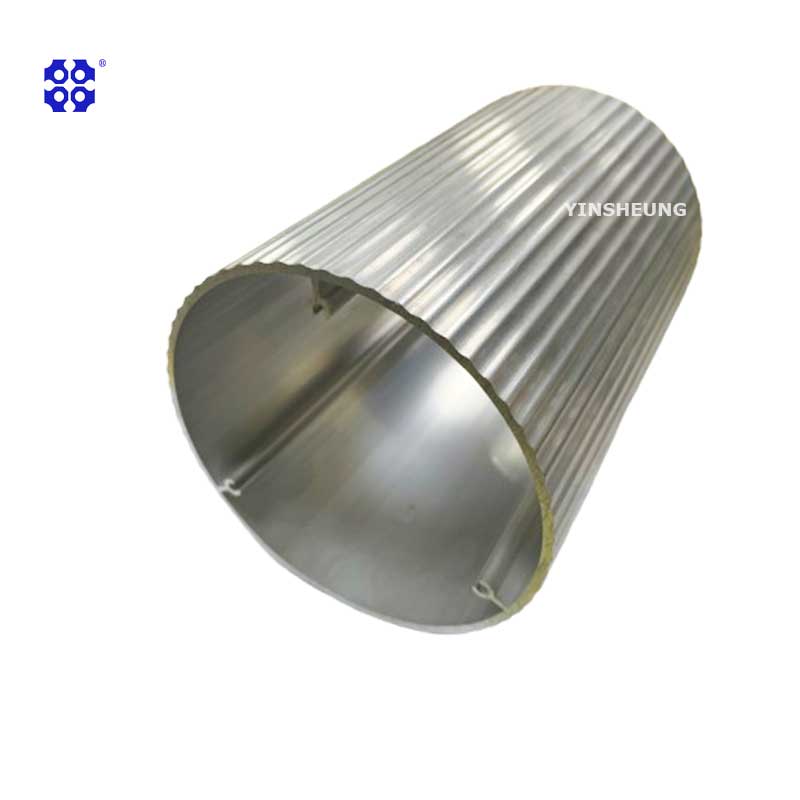

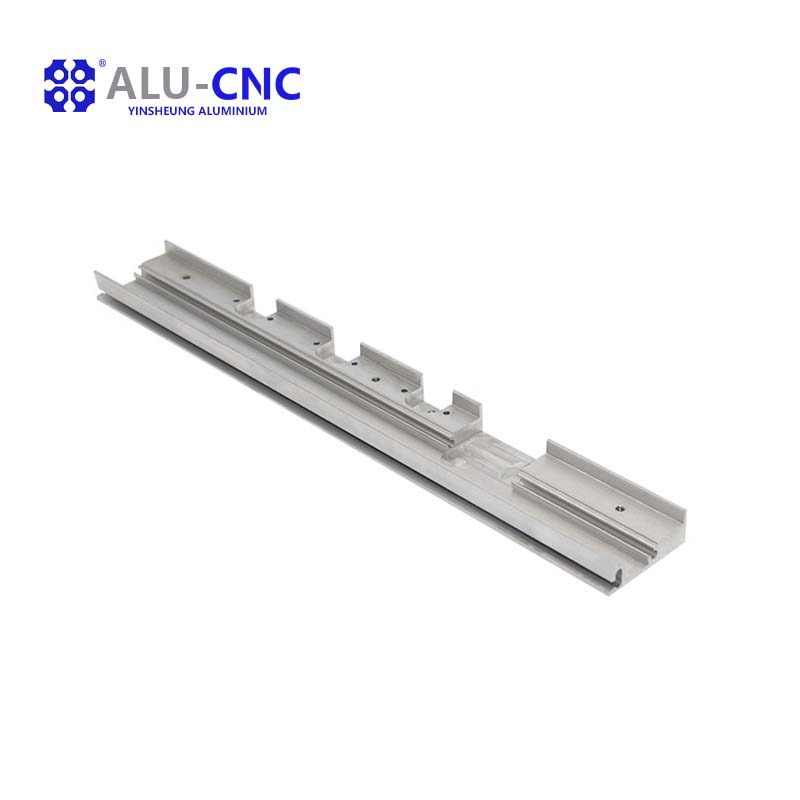

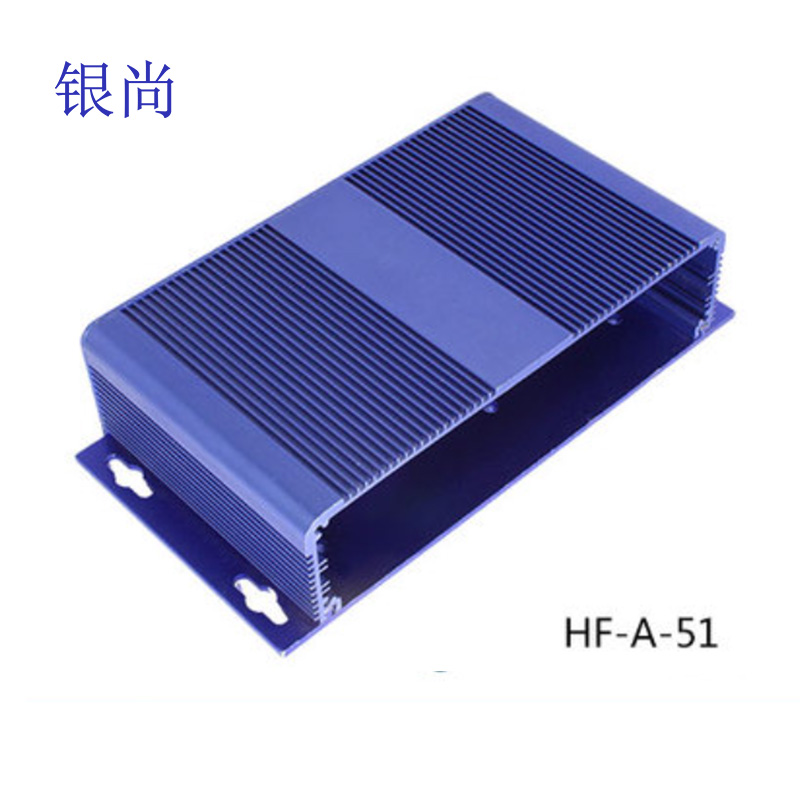

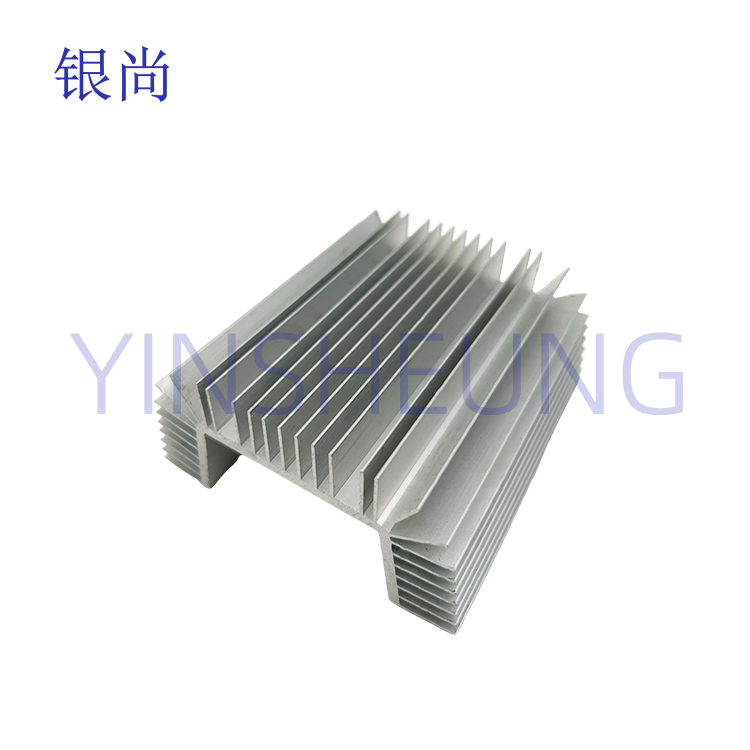

Foshan Yinsheung Aluminum Industry is continuously transforming and upgrading its extrusion equipment to meet the high-performance and dimensional accuracy requirements of industrial profiles. In order to better develop the high-performance and high-strength requirements of industrial profiles, they have started with aluminum alloys and developed customer alloy performance requirements. Currently, the enterprise is preparing to update new smelting furnace equipment, starting from alloying, and carry out high-quality control at the source.

Later, a product line of deep processing equipment was added, including a 6-meter CNC machine tool, a milling and sawing integrated CNC center, and precision sawing equipment.

2

Visiting Gangxin Aluminum Industry

Gangxin Aluminum specializes in the entire production line manufacturing of aluminum surface treatment anodizing equipment. The high-quality demand for solar profiles has put forward higher and updated requirements for the entire equipment, intelligent software, production line process energy consumption, and environmental protection and governance system facilities of the anodizing production line. Yuanchen Machinery has accumulated nearly 20 years of technical strength, adopting new design concepts in the entire production line design, equipment configuration, and intelligent software programming. With these advanced design and manufacturing, it has achieved excellent performance in high-end solar energy production line manufacturing.

three

3

Visit Jiling Electric CO Ltd.

Jiling Electric specializes in mold heating furnaces and is one of the specialized representatives in mold heating furnace manufacturing. They have delved deeply into mold heating furnaces, applying the principles of electromagnetism, thermal radiation, and heat transfer theory of mold steel conductors, and have made their own expertise in the inconspicuous equipment field of aluminum processing mold furnaces. In recent years, with the rise of the automotive and transportation profile markets, the market demand for large cross-section profiles has increased. Large cross-section profiles cannot do without large tonnage extrusion, and even larger molds with diameters greater than 500mm are indispensable. But the larger the mold, the more uneven the heating, and the expertise of Jiling Electric precisely meets this demand. At present, the new generation of large-scale mold heating furnaces they manufacture have precise temperature difference control between the mold surface and the mold core, meeting the temperature control requirements of large tonnage extrusion machines for producing large cross-section profiles. They are comparable to the famous German mold furnace manufacturer IAS and are favored by many domestic aluminum profile manufacturers.

four

4

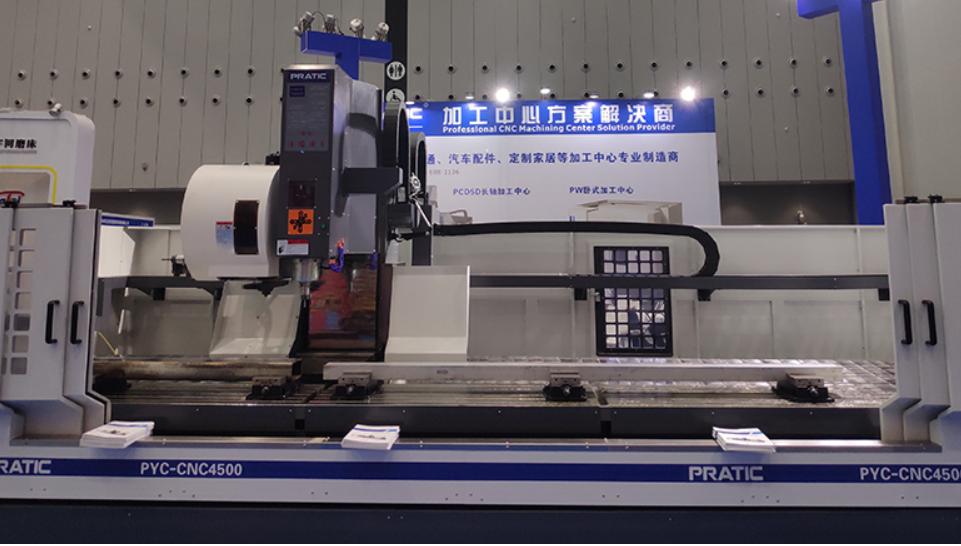

Visit Pradi Machinery

Pradi Machinery is currently a well-known manufacturer of deep processing mechanisms for aluminum profiles in China. With the improvement of packaging quality for aluminum profiles in China, they have developed a multi-functional folding packaging machine based on the existing bagging machine, which has improved the quality and aesthetics of aluminum profile packaging and is highly popular in the market.

5

Visit Lianyi Mold

Lianyi Precision Mold is one of the earliest and well-known aluminum extrusion mold equipment manufacturers in China. A few years ago, they collaborated with Japanese precision mold manufacturing companies, borrowing Japan's precision mold manufacturing technology for their own use. In the past two years, they have invested tens of millions to improve their factories, comprehensively update their mold manufacturing equipment, and added numerous five axis CNC machines. All the molds manufactured are completed in one go on the machine, eliminating manual involvement in the process of mold polishing, punch, and guide drilling. This ensures that the molds are fully integrated with the design drawings. After technological upgrades, the molds have truly achieved precision manufacturing.

Postscript

Although the current domestic aluminum processing industry appears to be struggling due to various factors, no matter what external environment it faces at any time, practicing internal skills and continuous innovation are the eternal winning weapons for enterprises. This is clearly felt from the specialized, refined, and new enterprises visited by the industrial alliance in recent years. We believe that with the gradual implementation and promotion of various policies such as "31 policies for the development of private economy" and "20 policies for promotion fees", the obstacles faced by the aluminum processing industry on the development path will gradually be eliminated, and the potential of aluminum consumption is expected to be further explored. We have reason to believe that aluminum processing enterprises with "specialized, refined, and innovative" advantages will become the biggest beneficiaries.