Full Introduction 1000-9000 Series Aluminum Alloys In This Article

Yinsheung CNC machining Aluminum 2023-12-02 Published in Foshan

1000 Series

Such as: 1060 1070 1100, etc

Features: Contains over 99.00% aluminum, has good conductivity, corrosion resistance, good welding performance, low strength, and cannot be strengthened by heat treatment Due to the absence of other technical elements, the production process is relatively simple and the price is relatively cheap.

Application scope: High purity aluminum (with an aluminum content of over 99.9%) is mainly used for scientific experiments, chemical industry, and special purposes.

2000 Series

Such as: 2017, 2024, etc

Features: Aluminum containing alloy with copper as the main alloying element. Manganese, magnesium, lead, and bismuth will also be added to improve cutting performance (with a copper content between 3-5%).

For example, in the melting process of 2011 alloy, attention should be paid to safety protection (which may produce harmful gases). 2014 alloy is used in the aviation industry with high strength. The strength of 2017 alloy is slightly lower than that of 2014 alloy, but it is relatively easy to process. 2014 can be strengthened through heat treatment.

Disadvantage: Severe intergranular corrosion tendency. Application scope: Aviation industry (2014 alloy), screws (2011 alloy), and industries with higher operating temperatures (2017 alloy).

3000 Series

Such as: 3003, 3004, 3005, etc

Features: Aluminum alloy with manganese as the main alloying element (with manganese content ranging from 1.0% to 1.5%). Non heat treatable strengthening, good corrosion resistance, good welding performance, and good plasticity (similar to super aluminum alloy).

Disadvantages: Low strength, but strength can be strengthened through cold work hardening; During annealing, it is easy to produce coarse grains.

Application scope: Seamless oil guide tubes (3003 alloy) and cans (3004 alloy) used on aircraft.

4000 Series

Such as: 4004 4032 4043

4000 series Aluminum alloy is an aluminum alloy with silicon as the main alloying element (with a silicon content between 4.5-6).

Most of these alloys belong to heat treated non strengthening aluminum alloys. Only alloys containing copper, magnesium, and nickel, as well as those that absorb certain elements after welding heat treated strengthening alloys, can be strengthened through heat treatment.

Due to its high silicon content, low melting point, good melt fluidity, easy shrinkage, and no brittleness in the final product, this series of alloys is mainly used as additive materials for aluminum alloy welding, such as brazing plates, welding rods, and welding wires.

In addition, due to the good wear resistance and high-temperature performance of some alloys in this series, they are also used to manufacture pistons and heat-resistant parts. An alloy containing about 5% silicon turns black gray after anodizing and coloring, making it suitable for use as building materials and manufacturing decorative parts.

5000 Series

Such as: 5052 5083 5754

Features: Mainly composed of magnesium (with a magnesium content between 3-5%).

Low density, high tensile strength, high elongation, good welding performance, good fatigue strength, cannot be strengthened by heat treatment, can only be improved by cold processing to enhance strength.

Application scope: handle of lawn mower, aircraft fuel tank duct, tank material, bulletproof vest, etc.

Generally, shoe racks at the mid-range and above are mostly 6 series or 7 series

6000 Series

Such as: 6061 6063

Features: Mainly composed of magnesium and silicon.

Mg2Si is the main strengthening phase and is currently the most widely used alloy.

6063 and 6061 are the most commonly used, while others 6082, 6160, 6125, 6262, 6060, 6005, 6463. 6063, 6060, and 6463 have relatively low strength in the 6 series. 6262, 6005, 6082, and 6061 have relatively high strength in the 6 series. The middle shelf of Cyclone 2 is 6061

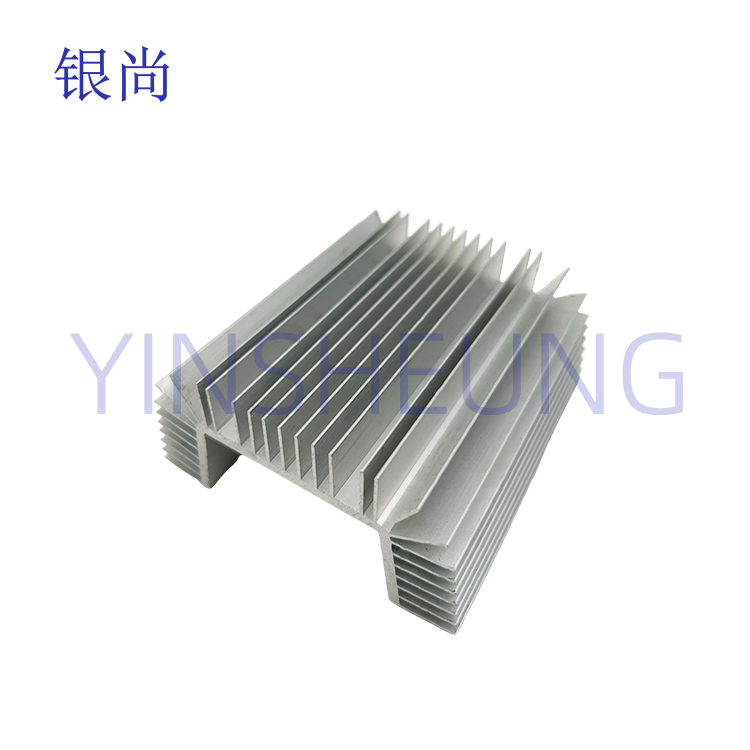

Features: Medium strength, good corrosion resistance, good welding performance, good process performance (easy to extrude), good oxidation coloring performance.

Application scope: Transportation vehicles (such as car luggage racks, doors, windows, body, heat sinks, compartment shells, phone cases, etc.)

7000 Series

Such as: 7050 7075

Features: Mainly zinc, but sometimes a small amount of magnesium and copper are added. Among them, superhard aluminum alloy contains zinc, lead, magnesium, and copper alloys with a hardness similar to that of steel.

The extrusion speed is slower than that of 6 series alloys, and the welding performance is good.

7005 and 7075 are the highest grades in the 7 series and can be heat treated for strengthening.

Application scope: aviation (load-bearing components and landing gear of aircraft), rockets, propellers, and aerospace spacecraft.

8000 Series

Such as: 8011 (rarely made with aluminum plates, usually used as aluminum foil)

Usage: Air conditioner aluminum foil, etc

9000 Series

Spare alloy