【Automotive aluminum】 The market prospects for new energy vehicle aluminum are broad

The outbreak of new energy cannot be separated from the support of aluminum materials, and the sales of new energy vehicles have reached a new high this year! According to statistics, China's production and sales of new energy vehicles have reached 2.566 million and 2.542 million respectively, a year-on-year increase of 1.8 times. By 2025, China's new energy vehicles will account for 35% of total vehicle sales, and the new energy vehicle processing industry will enter a golden period of development.

What is the relationship between the development of the new energy vehicle industry and the aluminum industry?

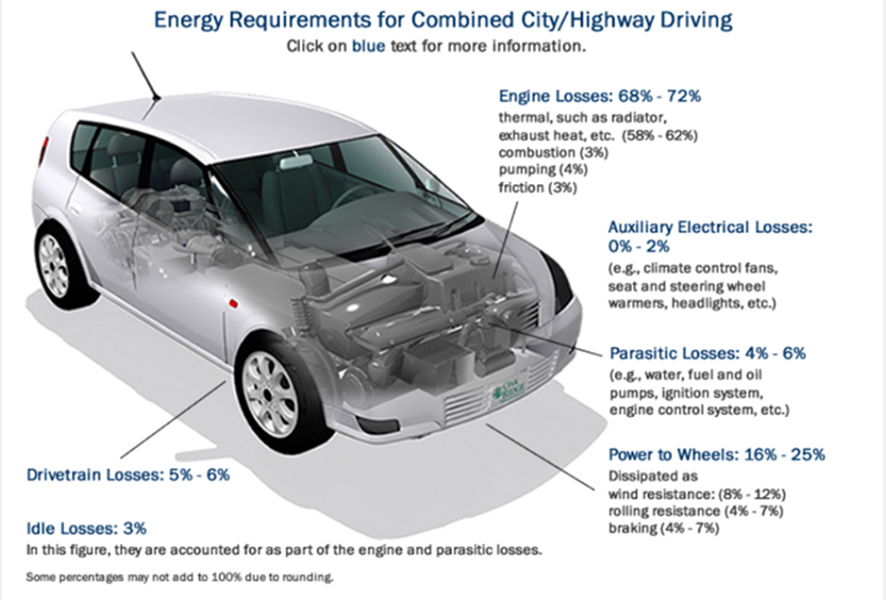

Firstly, we need to understand that the wheels, engine components, chassis, shock absorber brackets, and space frames in cars are all made of aluminum alloy, most of which are cast aluminum alloys. However, this alloy has a heavier weight, and for new energy vehicles, the lighter the weight, the more advantageous the range. For pure electric vehicle models, if the weight of the entire vehicle is reduced by 10kg, the range can be increased by 2.5km. Therefore, there is an urgent need for some lightweight alloys, However, the production process of lightweight alloys is relatively complex. Currently, in the domestic new energy vehicle industry, NIO, BYD, BAIC New Energy, and others have increased their automotive lightweight layout, bringing huge opportunities to aluminum processing enterprises.

How much aluminum is expected to be used in vehicles in the future?

It is expected that by 2025, the aluminum consumption of new energy vehicles in China will reach 1.76 million tons, while that of traditional vehicles will reach 4.46 million tons. The prospect of aluminum usage in vehicles is broad, and with the development of industry and the application of global green energy, aluminum usage will become a hot topic.

#powdercoating processing

#aluminumalloyprofiles

#aluminummaterial

#factories

#BatteryElectricVehicle

#BEV