1、 What is aluminum alloy

cPure aluminum is divided into smelting products and pressure processed products. The former is represented by Chemical composition Al, and the latter is represented by Pinyin LV (aluminum, industrial). Aluminum alloys can be divided into two categories according to processing methods: deformed aluminum alloys and cast aluminum alloys:

Characteristics and advantages and disadvantages of aluminum alloys

Compared to commonly used steel materials, aluminum has the following important characteristics and advantages. Based on these characteristics and advantages, aluminum and its alloys have been widely used in many fields.

Advantages of Aluminum

Disadvantages of Aluminum

·

Aluminum has a relatively low hardness, while its wear resistance is also poor.

·

·

The volume shrinkage rate of aluminum during solidification is relatively large, approximately 6.6%

·

·

Aluminum has a relatively high coefficient of linear expansion

·

·

The melting point of aluminum is relatively low, and the use temperature of aluminum and aluminum alloys cannot exceed 200 ° C, so their high-temperature use is limited. The elastic modulus of aluminum is only 1/3 of that of steel

·

·

The electrode potential of aluminum is very negative, so when aluminum comes into contact with dissimilar metals, it is prone to severe galvanic corrosion as an anode.

·

2、 Development History of Aluminum Alloys

It was not until 1825 AD that humans first produced a few milligrams of aluminum powder. Aluminum was discovered later, and aluminum smelting technology matured even later. Aluminum and its alloys are inferior to other metals, both in the discovery of metallic elements and as a structural material. However, the emergence of aluminum and aluminum alloys has greatly promoted industrial civilization, especially the development of aerospace technology and industry

3、 Aluminum alloy industry chain

Source: New Materials Online

4、 The Road to Transformation of Aluminum Alloys

Aluminum alloy is the most widely used non-ferrous metal structural material in industry, which has been widely used in aviation, aerospace, automotive, consumer electronics, mechanical manufacturing, shipbuilding, and chemical industries. Below, we will introduce the path of aluminum alloy transformation from the fields of aviation, aerospace, automotive, and consumer electronics.

Analysis of Aerospace "Aluminum" Development Stage of Aerospace Aluminum Alloys

Aviation aluminum is an ultra-high strength deformed aluminum alloy widely used in the aviation industry. It has good mechanical and processing properties, good plasticity after solution treatment, good heat treatment strengthening effect, and generally has high strength and toughness below 150 ℃ (or even higher), making it an ideal structural material. In addition, aviation aluminum materials are lightweight and have significant lightweight effects, replacing steel and occupying the dominant position in current aviation materials. Aviation equipment has high requirements for aluminum, making it an important high-end application market for aluminum materials

Advantages of aviation aluminum

Application advantages: Aluminum alloy, due to its high specific strength, good formability and processing performance, will also be the main structural material for the development of large aircraft in China.

Application areas: wing skin, wing surface stringers, upper and lower edge strips of wing beams, web plates, fuselage stringers, seat rails, keel beams, side frames, fuselage skin, fuselage lower wall panels, main floor stringers, etc.

Application proportion: A380-800 Airbus aluminum alloy materials account for the largest proportion, reaching 61%, A350-900XWB Airbus aluminum alloy materials account for 20%, and Boeing 787-8 Airbus aluminum alloy materials account for 15% -20%.

Commonly used aluminum alloy series

Nowadays, aluminum alloys used for large aircraft structures in various countries around the world are mainly high-strength ××× Series (6063, 6463, 6082, 6005, 6061 etc.) and ultra high strength 7 ××× Series (7075, 7475, 7050, 7150, 7055, 7085).

Development direction of aviation aluminum

The future research of aluminum alloys will focus on the following aspects: Aluminium–lithium alloys, aluminum matrix composites and superplastic formed aluminum alloys.

Aluminium–lithium alloys

Aluminium–lithium alloys is a multi-element aluminum alloy containing lithium. Lithium is the lightest metal element, and for every 1% increase in lithium in aluminum alloys, the density can be reduced by 3% and the modulus can be increased by 5%. In addition to the advantages of light weight, high modulus and high strength, Aluminium–lithium alloys also has excellent fatigue resistance and good low-temperature toughness, and its strength can be comparable to 2024, 7075 and other aluminum alloys. In view of this, Aluminium–lithium alloys has been deeply loved by the aerospace industry. As a new aerospace structural material, it has become a hot spot of research and development in the United States, Britain, France, Russia and other developed countries.

Aluminum based composite materials

Aluminum based composite materials have attracted widespread attention due to their advantages such as low density, high specific strength and stiffness, high specific elastic modulus, good conductivity and thermal conductivity, high temperature resistance, oxidation resistance, corrosion resistance, and flexible preparation processes.

For a long time, due to the complex preparation process, strict environmental and equipment requirements, and high cost of aluminum based composite materials, their application has not been widespread.

Superplastic formed aluminum alloy

The superplastic forming of aluminum alloys is achieved through deformation and heat treatment with a yield of less than 10% μ These ultra-fine grain alloys can achieve superplasticity under conditions of higher than half melting point and low strain rate, and can form components with light weight, low cost, and complex shape that are difficult to obtain by traditional methods. They also have many advantages such as low forming pressure, long mold life, and the ability to form accurately in one go.

Analysis of "Aluminum" in Consumer Electronics: Development Stage of Aluminum Alloys in Consumer Electronics

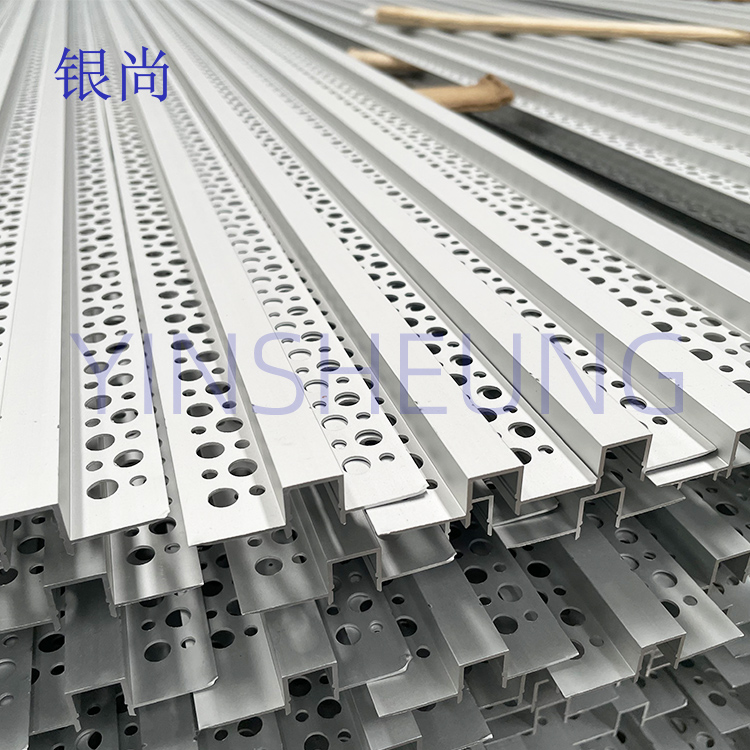

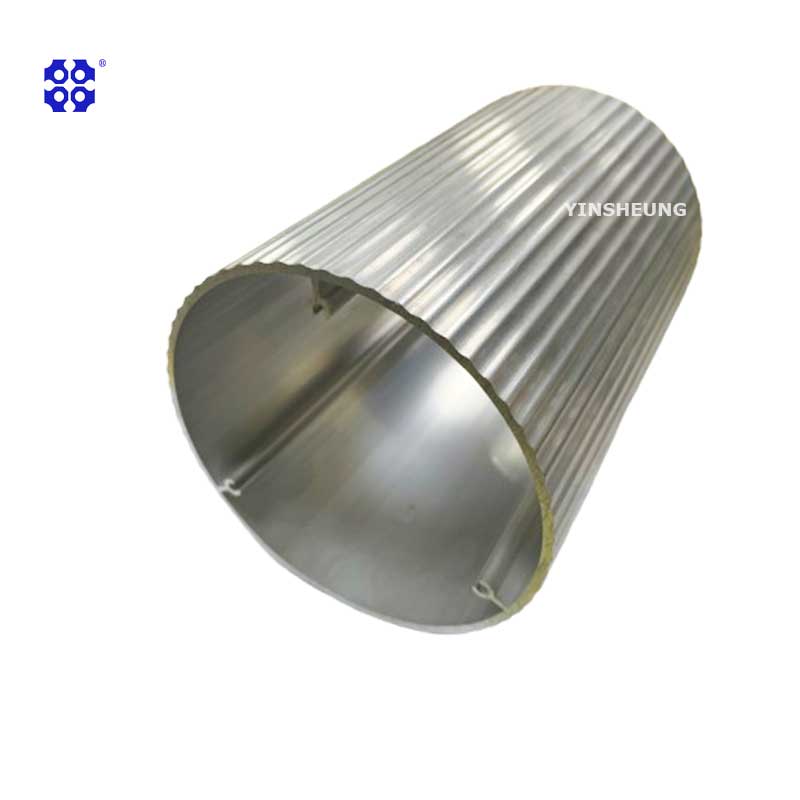

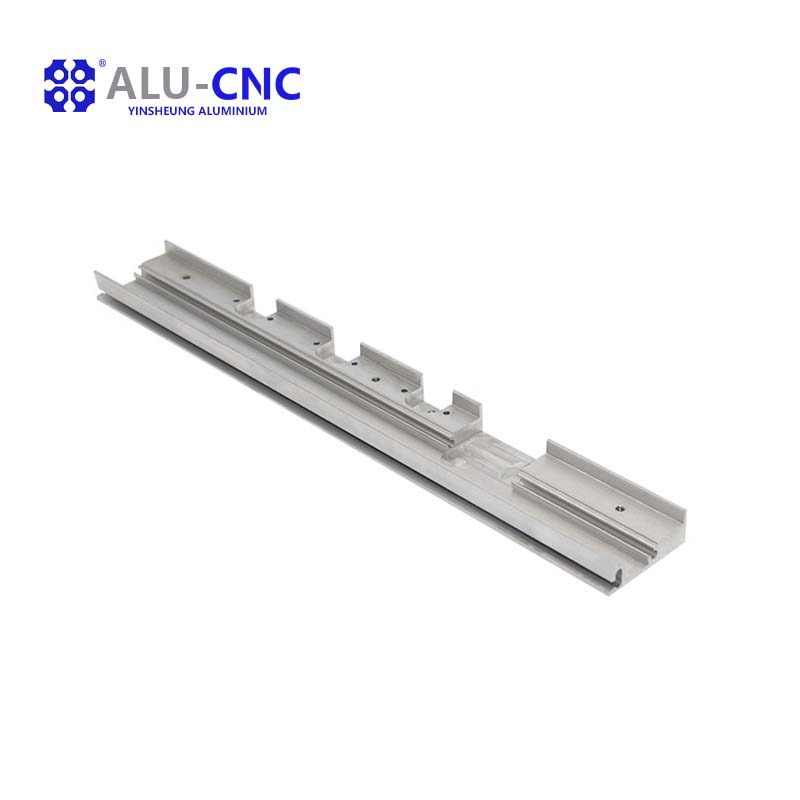

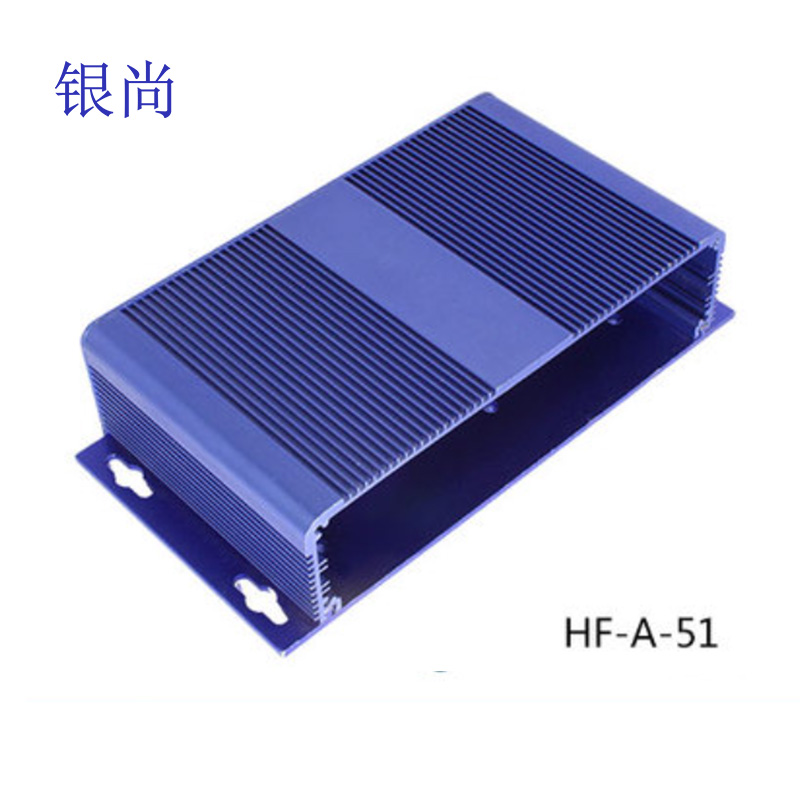

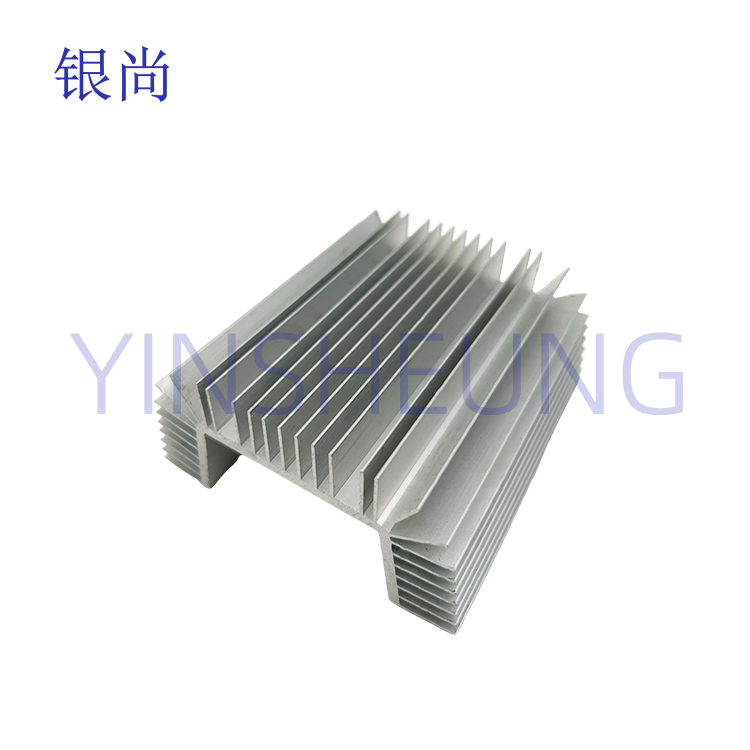

Aluminum alloy is the most common nonferrous metal products, which is closely related to us, namely, aluminum products for consumer electronics. Aluminum alloy is mainly embodied in the form of shell, frame, radiator and aluminum tube in Consumer electronics.

Application of Aluminum for Consumer Electronics

Market Analysis of Aluminum for Consumer Electronics

At present, the scale of the consumer electronics market has entered a stage of stable development, and in mature markets, secondary purchasing has become the mainstream. Consumers and consumer electronics companies are increasingly paying attention to the appearance design and material craftsmanship of their products.

According to the White Paper on Aluminum in the Chinese Consumer Electronics Industry (2016), the total amount of aluminum used in finished products sold by sample companies in the domestic consumer goods market in 2016 was nearly 20000 tons, a year-on-year increase of nearly 35%, far higher than the growth rate of the consumer electronics market during the same period.

It is expected that the demand for aluminum in the four consumer electronics fields of mobile phones, tablets, mobile power supplies, and televisions in China will be approximately 120000 tons in 2016, and it is expected to increase to nearly 20 tons in 2018

Aluminum Rookie for Consumer Electronics -7075 Alloy

The "bending door" of the iPhone 6 plus has hurt the hearts of a generation of fruit powder. In order to solve the problem of poor bending resistance of the iPhone 6 plus phone body, the aluminum industry suggested that Apple use the ultra strength aluminum alloy 7075 plate used in aerospace industry to process the body. The iPhone 6S and iPhone 6S plus are all made of 7075 alloy plate produced by Alcoa, which has achieved the expected good results and greatly improved the bending resistance, The situation of bending after falling disappeared, and the deformation did not occur.

Introduction to 7075 Alloy

7075 alloy was developed by Alcoa for World War II aircraft and used to manufacture large bombers and fighter planes. It was finalized in 1944. Before July 1954, the brand was 75S. In July 1954, it was registered in the American Aluminum Association and changed to a unified four digit brand 7075.

For example, the front fuselage truss, passenger observation window frame, center fuselage truss, keel beam edge strip, keel beam web plate, floor turning beam, center and rear fuselage truss and cargo door frame, nose truss and edge strip, and cabin door frame of C919 aircraft are all made of different 7075 alloy materials. It can be said that without the support of 7075 aluminum alloy, such a high appearance, lighter, more comfortable, and faster large passenger aircraft cannot be built.

Application of 7075 alloy in the mobile phone industry

Among the world's mobile phone body materials, the new iPhone is not the only smart model that uses this super strong material. The ultra-thin body of Samsung's Note 5 and S6 edge in South Korea benefits from the use of 7075 alloy. Due to the excellent performance of 7075 alloy, the stability of the two smartphone bodies has reached an unprecedented new level. Since then, there has been no further bending or damage.

Short aluminum plates in the shell of mobile phones and electronic products urgently need to be fully repaired

There are various types of electronic products, and aluminum materials are also used in a wide variety of styles. Although the usage of a single product is not large, the production of electronic products is large, with millions, millions, and even hundreds of millions of pieces. Moreover, the replacement is very fast. Aluminum materials are widely used in the manufacturing of mobile phone bodies and electronic product shells, and now it is almost impossible to find electronic products that do not use aluminum materials.

At present and in the future, the trend of thin and light mobile phones is an irresistible trend, which needs stronger and better body materials to support. In the future, there will be more domestic mobile phones using 7xxx series alloy thick plates as body materials, but the plates used now are produced by Alcoa, and the import price is up to 70000 yuan/t, about 3.9 times the price of 3xxx series alloy. Except that the production process of 7075 alloy is much more complex than other alloys, Foreign companies have also seen that China is currently unable to produce aluminum alloy thick plates of this grade for mobile phones, making them a rare commodity.

Therefore, China must quickly overcome this dilemma and fill this gap. China's aluminum processing equipment fully meets the conditions for producing this type of aluminum plate. In fact, as early as 1957, Harbin Aluminum Processing (codenamed -0- factory, now known as Northeast Light Alloy Co., Ltd.) successfully produced aviation grade B95 (Soviet brand, equivalent to 7075) alloy material with the help of Soviet experts.

Of course, the processing technology of 7xxx alloy mobile phone body alloy sheet, including CNC cutting and anodizing coloring, is much more difficult than that of 6xxx series alloy sheet. Whether these problems can be successfully solved will become the key to the promotion and application of this alloy sheet in domestic mobile phones.

Analysis of "Aluminum" in the Automotive Industry: Development Stage of Aluminum Alloys for Automobile

The development of energy-saving and environment-friendly vehicles is an urgent need to alleviate fuel supply conflicts and reduce exhaust emissions, and also an inevitable choice for the sustainable and healthy development of China's automobile industry in the future. As a common key technology of energy-saving vehicles and Alternative fuel vehicle, automobile lightweight has also been widely promoted and applied.

The development of the world automotive industry faces three major themes: energy conservation, environmental protection, and safety. According to experimental verification by relevant research institutions, a 10% weight reduction in gasoline passenger cars can reduce fuel consumption by 3.3%, and a 15% weight reduction can correspondingly reduce fuel consumption by 5%.

Body lightweight is the inevitable choice of Alternative fuel vehicle under the condition of increasing the number of battery packs to improve the "range". With the rapid development and popularization of Alternative fuel vehicle, body lightweight is also increasingly valued. Advanced high-strength steel, aluminum magnesium Light metal, carbon fiber and other composites have become the three main directions of lightweight development.

The Application of Aluminum Alloys in Automobiles

Aluminum alloy is widely used in automobiles, with components such as power and transmission systems, body and interior/exterior systems, heat exchange systems, and wheels all made of aluminum alloy material.

Utilization rate of aluminum alloy for different components

(Source: The AluminumAssociation)

With the development of lightweight automobiles, the rapid growth of aluminum alloy applications in the future will mainly focus on body structural components such as panels and white body. The all-aluminum body will increase from 4% now to 18%, with an annual compound growth rate of over 16%.

Penetration rate of aluminum alloys in vehicle bodies and panels in the next 10 years

(Source: DUCKER WORLDWIDE)

Penetration rate of aluminum for automotive components in North America

(Source: duck worldwide)

By 2025, the proportion of car models using all aluminum body will reach 30%, and the global total amount of aluminum used in car bodies will reach 8.7 million tons, indicating explosive growth in the car body aluminum industry.

New directions for research and application of automotive aluminum materials

With the improvement of automobile aluminization, it is required to develop new types of aluminum alloys and aluminum materials with different specifications and varieties for different purposes. This will greatly promote the development of aluminum alloys and their processing technology, and promote the application of aluminum materials in the automotive industry. It can be foreseen that aluminum materials will partially replace steel as the basic material of the automotive industry. The expansion of automobile aluminization in the future will inevitably rely on the balance of demand for aluminum materials and production costs, Reducing the cost of aluminum materials and improving production efficiency is the future direction of efforts:

1. Research and development of new aluminum alloy body materials

2. Research and development of anti impact gear and rigid structural components for car doors

3. Research and Development Trends of Rotating Parts

4. Development of New Aluminum Alloy Heat Exchange Materials

5. Development of weldable medium strength aluminum alloy sheets for commercial vehicle fuel tanks and air compressor air storage tanks

6. Research and development of forged aluminum alloy wheels and structural components