Reasons for Stripes in Industrial Aluminum Profile

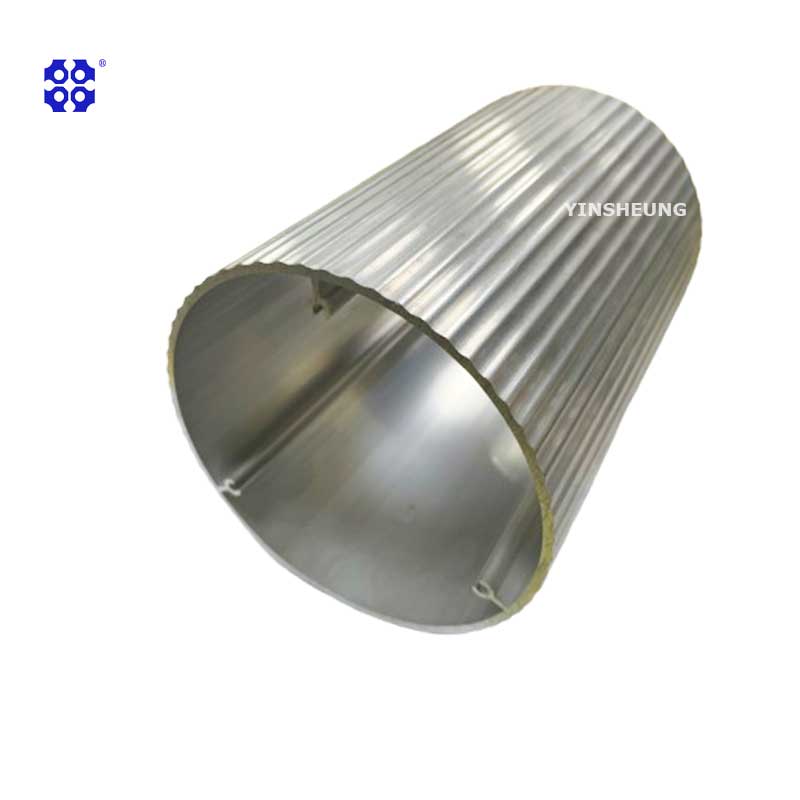

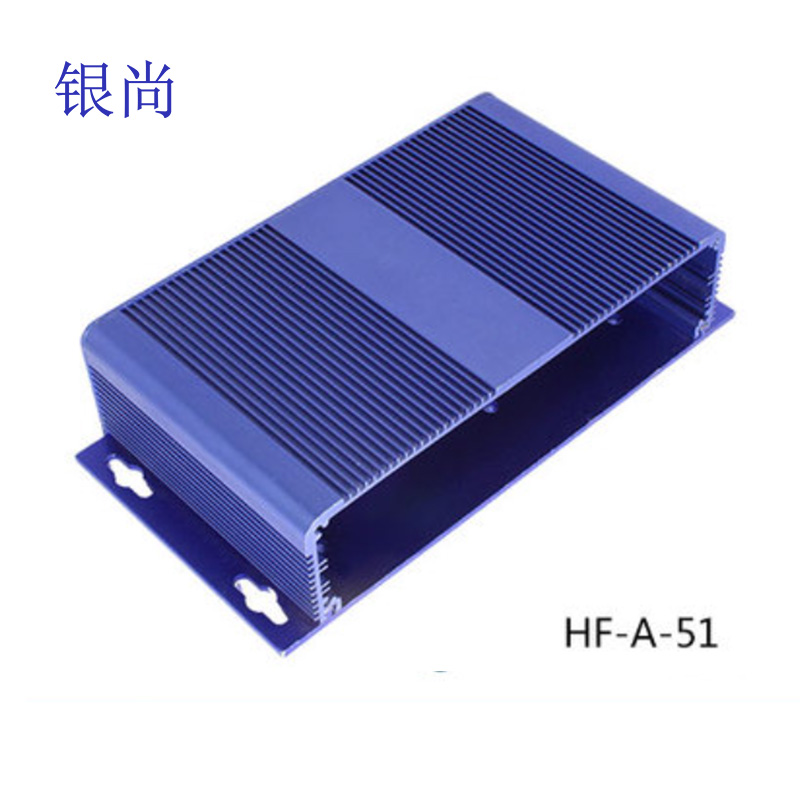

Industrial aluminum profiles are an alloy material mainly composed of aluminum. Aluminum rods are melted and extruded to obtain aluminum materials with different cross-sectional shapes. However, the proportion of added alloys varies, resulting in different mechanical properties and application fields of industrial aluminum profiles produced. When we produce industrial aluminum profiles, we sometimes encounter the problem of stripes. So how does the problem of stripes in industrial aluminum profiles arise? The causes of stripes on industrial aluminum profiles:

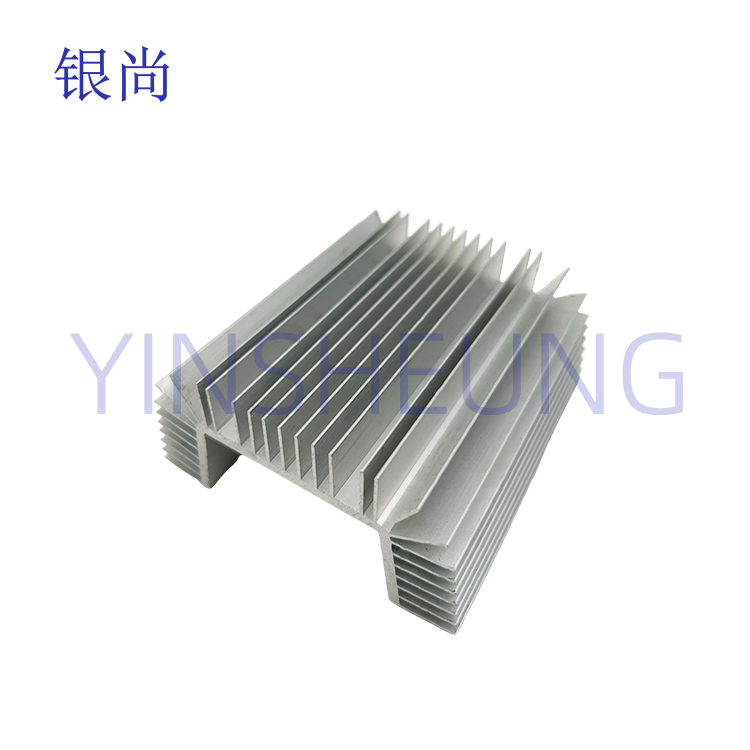

1. Due to insufficient cooling capacity of the machine, black striped areas are formed after anodizing.

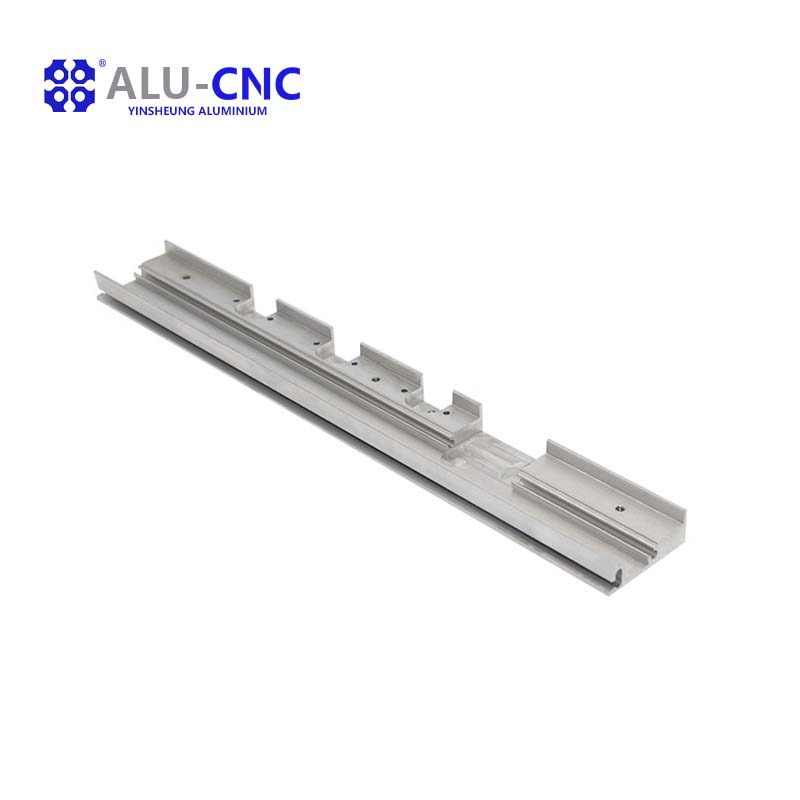

2. The "branches" and threaded holes on the inner side of the aluminum profile cause surface stripes due to insufficient or excessive metal supply.

3. The poor quality of the casting billet itself affects the color difference of the stripes after anodizing of the extruded material.

4. Stripes on the surface of the profile caused by the welding area under the mold diversion bridge.

https://img.yigetechcms.com/41/source/YS%20-_556__9880.jpg