Aluminum surface anodizing treatment

1 Aluminum surface anodized treatment method:

(1). Hot is water flushing:

Rinse with hot water at 40-50 degrees Celsius to form a protective film on the surface

(2). Drying:

First, use a towel to absorb surface moisture and let the aluminum material air dry naturally

(3). Aging:

Expose to sunlight or dry in an oven.

2 Benefits of aluminum anodizing:

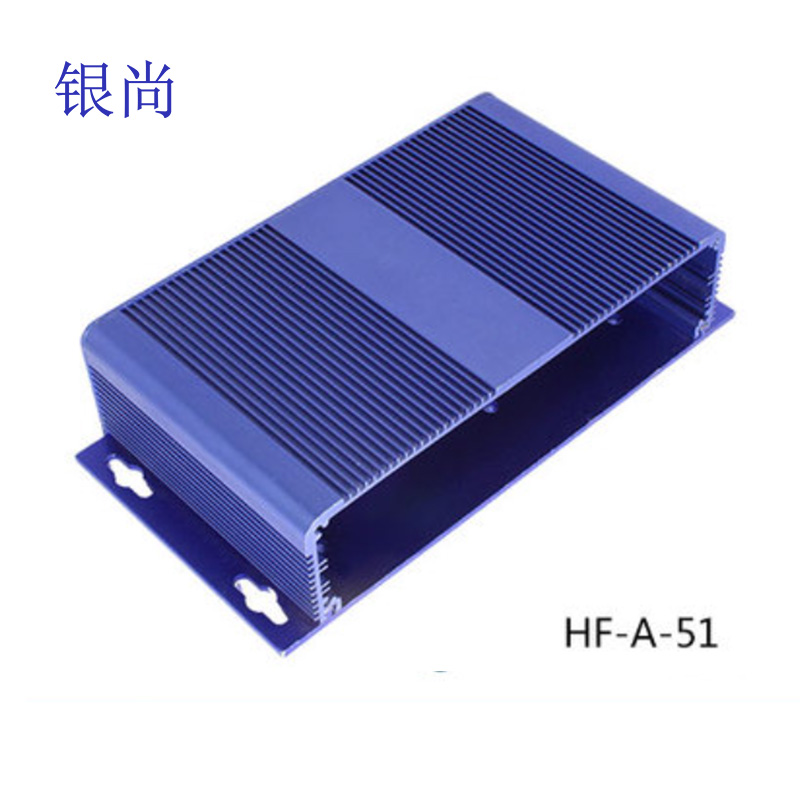

(1) To prevent corrosion of aluminum profile products:

Rinse the aluminum material with hot water to achieve the purpose of aging the film layer. However, when using this method, it is important to pay attention to the water temperature and strictly control the cleaning time.

Generally, the water temperature is around 40 to 50 degrees, and the cleaning time is controlled within one minute to prevent the color of the aluminum material from fading.

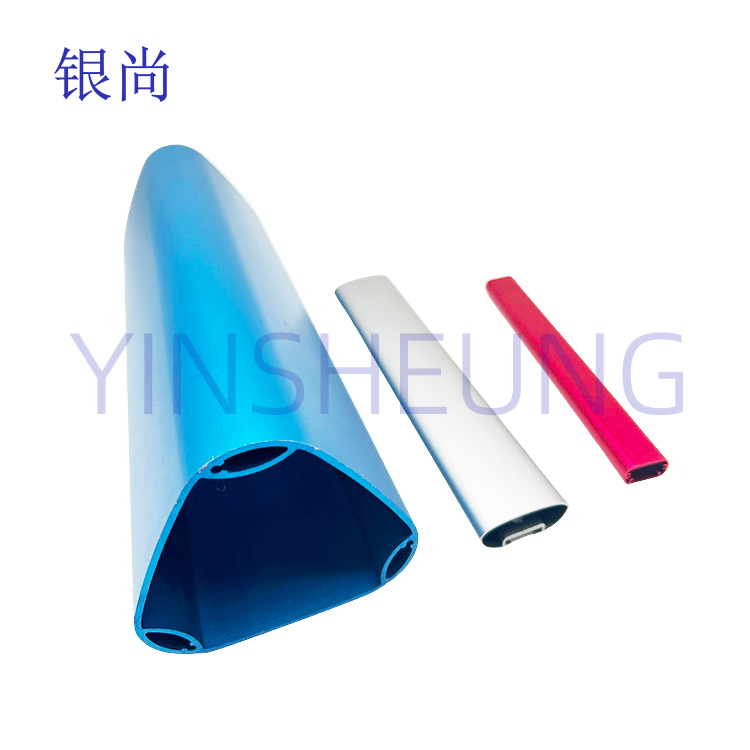

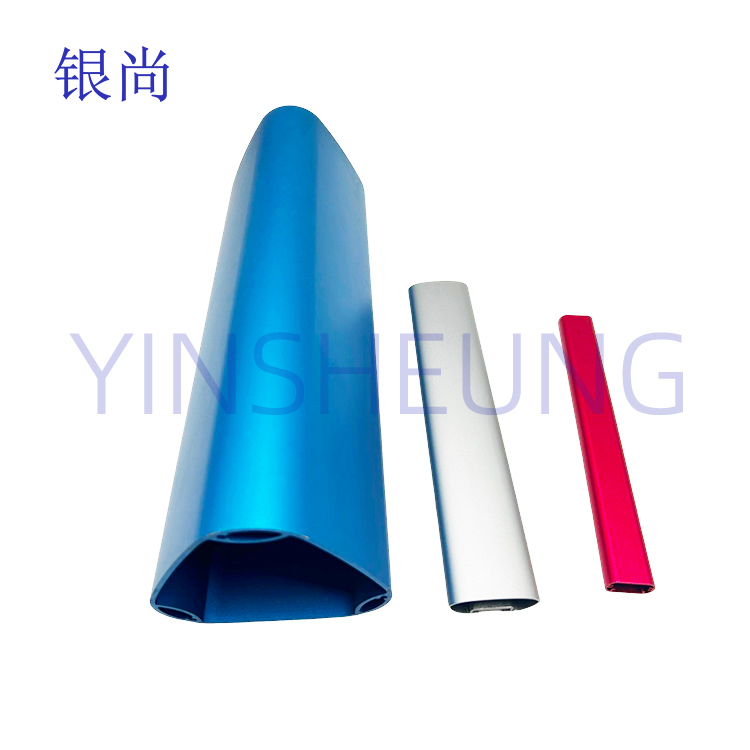

(2) Increase the aesthetics of the product:

The formed oxide film can adsorb various dyes, so the products can be designed into various bright patterns and colors, and the most representative ones should be other products such as lighters and gold pens.

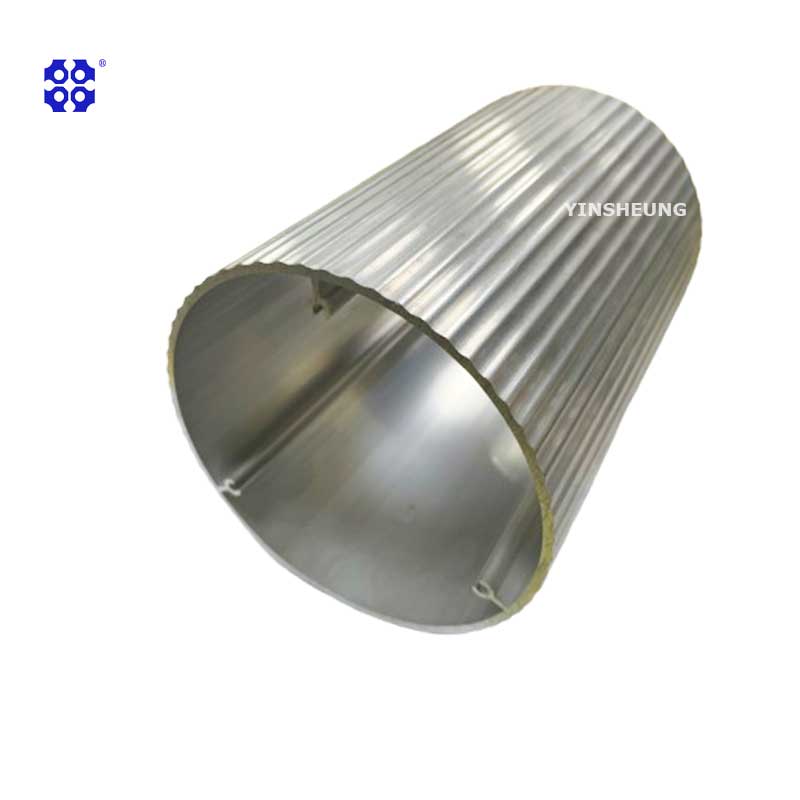

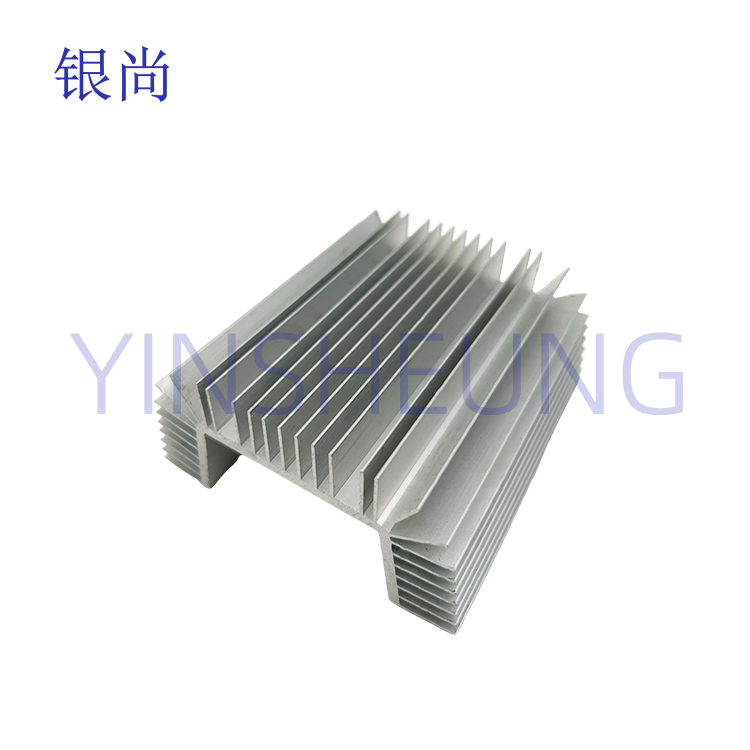

(3) Strong wear resistance:

The hardness of the anodized protective film is strong. This layer of protective film has excellent absorption, which can be used to store oil. The most representative ones are the engine cylinders and pistons of cars profile and tractors.

3 The difference between surface treatment of electroplating and anodizing of aluminum :

1. Different scope of application

(1) Electroplating:

Suitable for various surface treatments of metal and non-ferrous metal. As long as reasonable surface treatment is carried out, various metals and some non-metals can be electroplated.

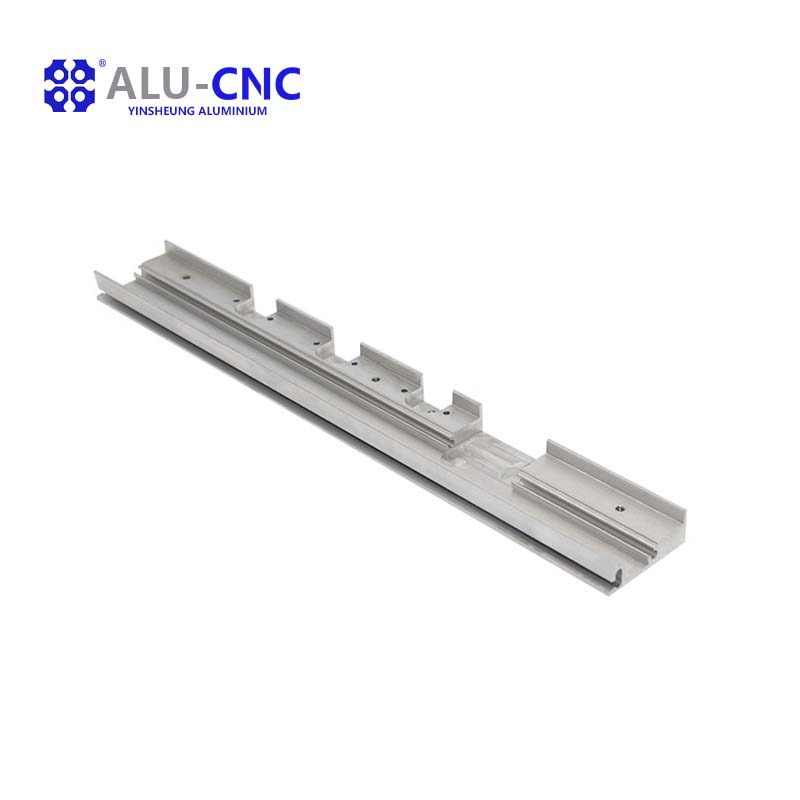

(2) Anodizing:

Not all metals are suitable for anodizing. Metal alloys are suitable for anodizing treatment, while aluminum alloy is the most widely used.

2. Different principles

(1) Electroplating:

The material being electroplated serves as the cathode, and the coating of gold serves as the anode for electrification. The coating of gold exists in the electrolyte in the form of gold ions.

(2) Anodizing:

It is achieved by using anodized aluminum profile as an anode and electrolyzing it with low voltage direct current to form a dense oxide film on the surface of the material, which is an anodized firm of its own metal surface.

3. Different protection methods

(1) Electroplating:

Electroplating involves adding another type of metal protective layer to the original material surface through physical effects.

(2) Anodizing:

Anodizing is the electrochemical anodizing of a layer on the surface of aluminum.