The processing technology for different colors of industrial aluminum profiles is certainly different, and the surface color of industrial aluminum profiles is obtained through different processing and surface treatment processes. The common technical processes on the market are anodizing treatment, electrophoresis treatment, spray surface treatment, and nano treatment. Not all of these processes can produce the desired colors. Each process has its own representative color. Below is a brief introduction.

Oxidation treatment

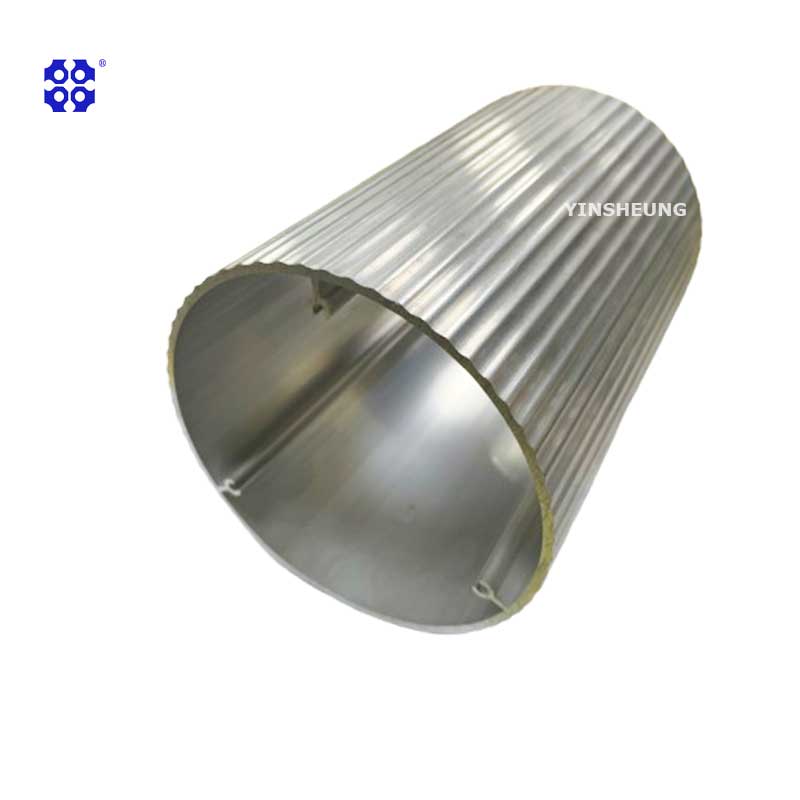

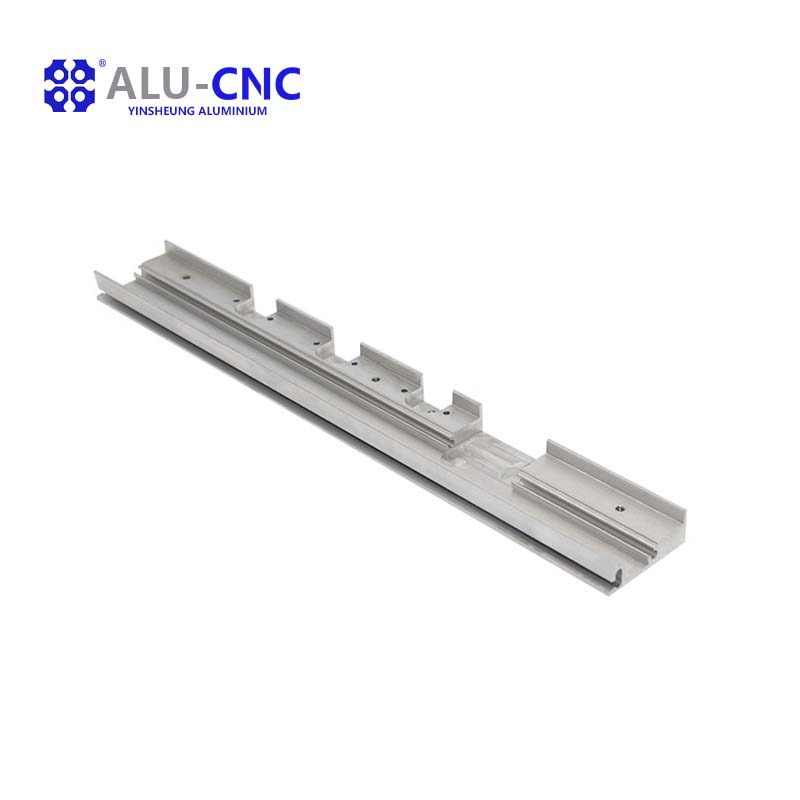

A common type is surface treatment anodizing, which is represented by silver white oxidation. Many models and specifications on the market use this color, although there are also oxidized black, only a few models and series will have this color.

Electrophoretic treatment

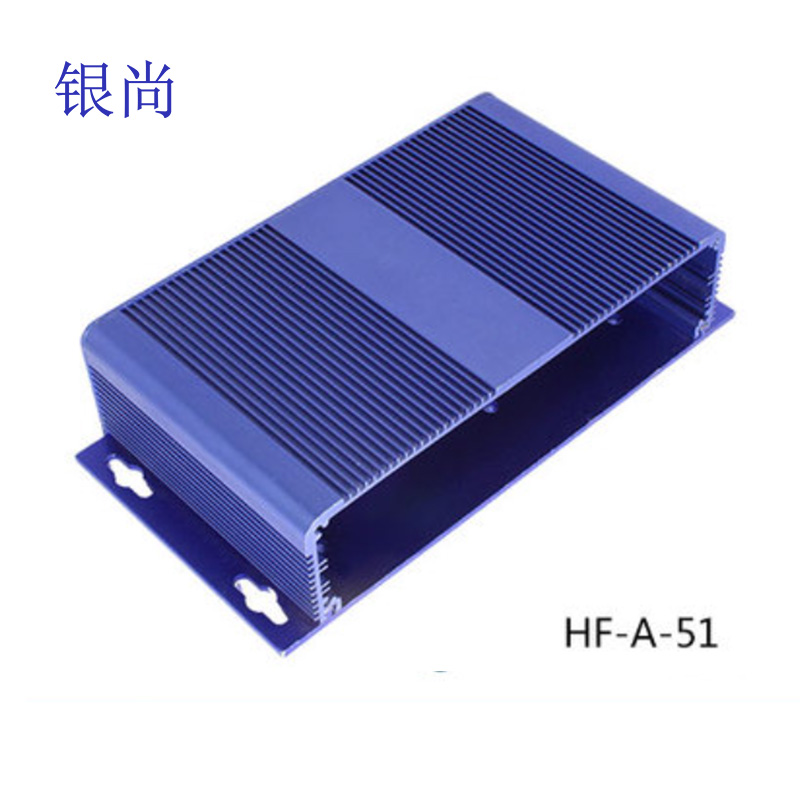

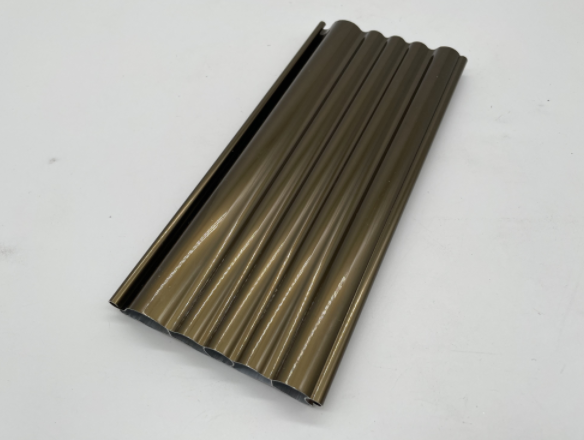

Electrophoresis treatment is rarely used by people, unless it is required to meet high standards. It has strong paint film hardness, strong impact resistance, high paint film adhesion, and is not easy to peel off and age. It has stronger wear resistance, weather resistance, and alkali resistance than aluminum oxide. Electrophoresis aluminum profiles are processed on the basis of aluminum oxide materials, with a quality that is one step higher than aluminum oxide materials, and naturally higher prices. The surface color is rich and beautiful, Has a mirror like luster effect. Long made colors include champagne, silver white, stainless steel, bronze, gold, and black.

Powder coating treatment

Compared with electrophoretic treatment, spraying treatment has many key points in terms of usage rate. It has the same cost as anodizing treatment, and can also be made in colors such as champagne, silver white, stainless steel, bronze, gold, and black.

Sandblasting treatment

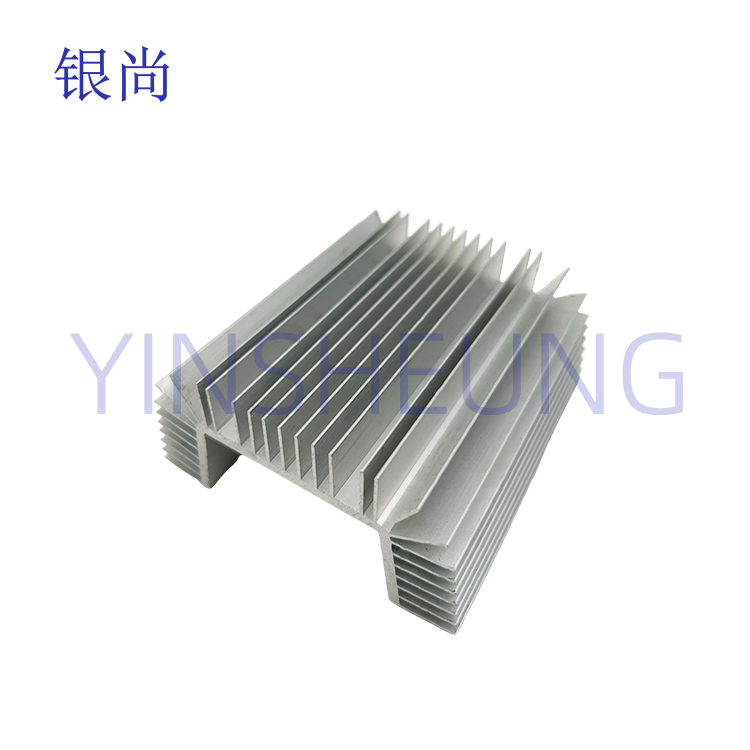

Aluminum alloy sandblasting oxidation surface treatment is a commonly used surface treatment method, which uses high-pressure gas to spray sand or other granular materials to remove the oxide layer and dirt on the surface of aluminum alloy, forming a certain roughness. Increasing the surface area can improve the corrosion resistance and wear resistance of aluminum alloy materials, and make their appearance more beautiful.