What is Aluminum Hydraulic Oil Tank?

It is one of the essential components of the new energy vehicle. It stores the fuel or energy source, which is used to power the vehicle. Lightweight materials such as aluminum extrusions have become popular for designing fuel tanks due to their high strength-to-weight ratio, durability, and cost-effectiveness.

INQUIRYWhat is Aluminum Hydraulic Oil Tank?

It is one of the essential components of the new energy vehicle. It stores the fuel or energy source, which is used to power the vehicle. Lightweight materials such as aluminum extrusions have become popular for designing fuel tanks due to their high strength-to-weight ratio, durability, and cost-effectiveness.

Product Processing

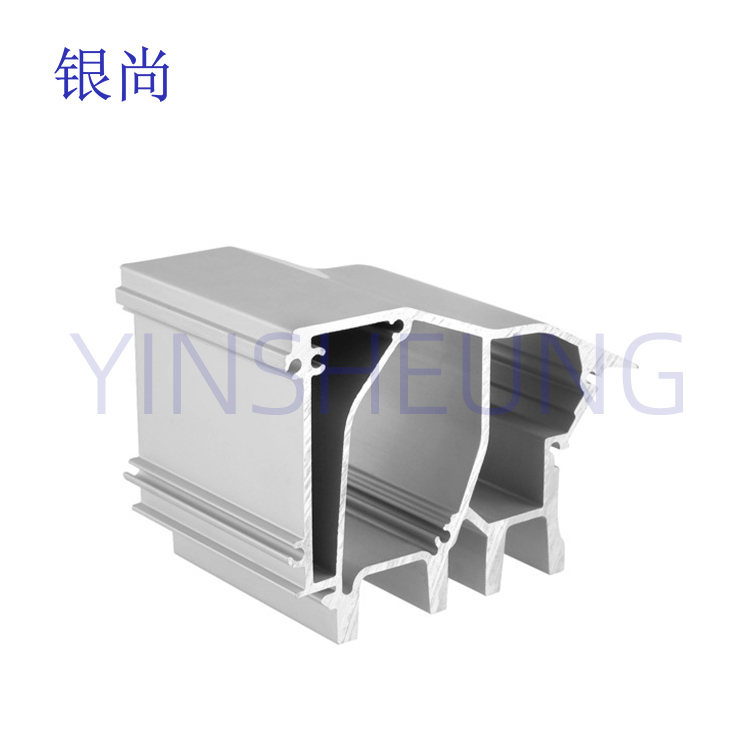

The aluminum hydraulic oil tank extrusion process involves heating the aluminum billet to a specific temperature and then forcing it through a die of the desired shape. The die shapes the aluminum into a specific dimension, which can then be cut to the required length. The final product is a highly durable, strong, and lightweight aluminum extrusion used in a variety of applications, including automotive fuel tanks.

Basic Information

|

Product Name |

aluminum hydraulic oil tank |

|

Aluminum Range |

Extrusion for aluminium hydraulic oil tank, hydraulic oil tank, oil tank, oil catch tank diesel, oil storage tank, oil heating tank, aluminium hydraulic tank, oil tank heater, tank for oil |

|

Aluminum Alloy |

1000 series, 200 series, 3000 series, 5000 series, 6000 series, 7000 series |

|

Temper |

T3-T8 |

|

Shape |

customization |

|

Color |

customization |

|

Surface Treatment |

mill finished, anodized, wood grain, power coating, sand blasting, electrophoresis, brushed, polishing, etc |

|

CNC Deep Processing |

cutting, drilling, machining, punching, bending, tapping and so on |

|

Certifications |

CE, ISO, SGS, TUV, ROHS |

|

Samples |

free sample. 1-3 days delivered to you. |

|

MOQ |

500KG for each profile |

|

Delivery Time |

Mold developing and sample conformation is 12-15 days, then production duration is 15-25 days after receipt of deposit from buyer. |

|

Payment Terms |

30% deposit before production, and balance before shipment. |

|

Port |

Shenzhen, Guangzhou |

Features Of Aluminum Hydraulic Oil Tank

1. High gas tightness:

It is essential for the safe storage and transportation of hydrogen gas. Unlike gasoline, hydrogen is a highly flammable gas that can be dangerous if not handled properly. Therefore, it is critical that the hydrogen fuel tank has a high level of gas tightness to prevent any leaks or explosions. Hydrogen fuel tanks are made of materials such as carbon fiber and aluminum, which are known for their high strength and low weight. These materials are also resistant to corrosion and can withstand high pressures, making them ideal for storing hydrogen gas.

2. Precision welding processing:

It is critical to ensuring the structural integrity and performance of the hydrogen fuel tank. A hydrogen fuel tank requires multiple welding processes to assemble its various components, such as the tank body, end caps, and fittings. The quality of these welds is crucial to the tank's durability and safety, as any defects or cracks could lead to leaks or failures. Therefore, precision welding processing is essential to achieve consistent and high-quality welds.

Advantages Of Using Aluminum Hydraulic Oil Tank:

1. Lightweight: Aluminum is a lightweight material that reduces the overall weight of the vehicle, thereby improving fuel efficiency and reducing emissions.

2. High strength-to-weight ratio: Aluminum extrusions have a high strength-to-weight ratio, making them stronger than steel and other materials, despite being lighter.

3. Corrosion resistance: Aluminum extrusions are highly resistant to corrosion which prevents fuel leaks and ensures the safety of passengers.

4. Cost-effective: Aluminum extrusions are cheaper than traditional fuel tanks made of steel or other materials.