What is the difference between 6060 aluminum alloy and 6063 aluminum alloy

Yinsheung Deep Processing 2023-10-04 10:18 Published in Foshan

The chemical composition and processing properties of 6060 and 6063 aluminum alloys are similar, but not completely the same. The difference between the two lies in their strength. 6060 is a national standard aluminum alloy for doors and windows, while 6063 is a nationally licensed aviation aluminum alloy.

6060 aluminum material composition

Si: 0.3-0.6

Fe: 0.1-0.3

Cu: 0.1 Mn: 0.1

Mg: 0.35-0.6

Cr: --

Zn: 0.1

Other: --

Ti: 0.15

Other

total: 0.15

Al: Surplus performance: tensile strength σ B (MPa): ≥ 470 conditional yield strength σ 0.2 (MPa): ≥ 420 elongation δ 5 (%): ≥ 6

Product features:

1. High strength heat-treatable alloy.

2. Good mechanical performance.

3. Good usability.

4. Easy to process and good wear resistance.

5. Good corrosion resistance and oxidation resistance.

Main applications: aviation fixtures, trucks, tower buildings, ships, pipelines, and other applications in buildings that require strength, weldability, and corrosion resistance. For example: aircraft parts, camera lenses, couplers, ship accessories and hardware, electronic accessories and connectors, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves and valve parts.

6063 aluminum alloy chemical composition:

aluminum Al: residual silicon

Si: 0.20-0.6

copper Cu: ≤ 0.10

magnesium Mg: 0.45-0.9

zinc Zn: ≤ 0.10

manganese Mn: ≤ 0.10

titanium Ti: ≤ 0.10

chromium Cr: ≤ 0.10

iron Fe: 0.000-0.350

Note: single: ≤ 0.05;

Total: The density of ≤ 0.15 6063 is 2.69g/cm3

Physical characteristics and mechanical properties:

Tensile strength σ B (MPa): ≥ 205 conditional yield strength σ 0.2 (MPa): ≥ 170 elongation δ 5 (%): ≥ 9 6063 Aluminum Plate Product Features and Usage Introduction:

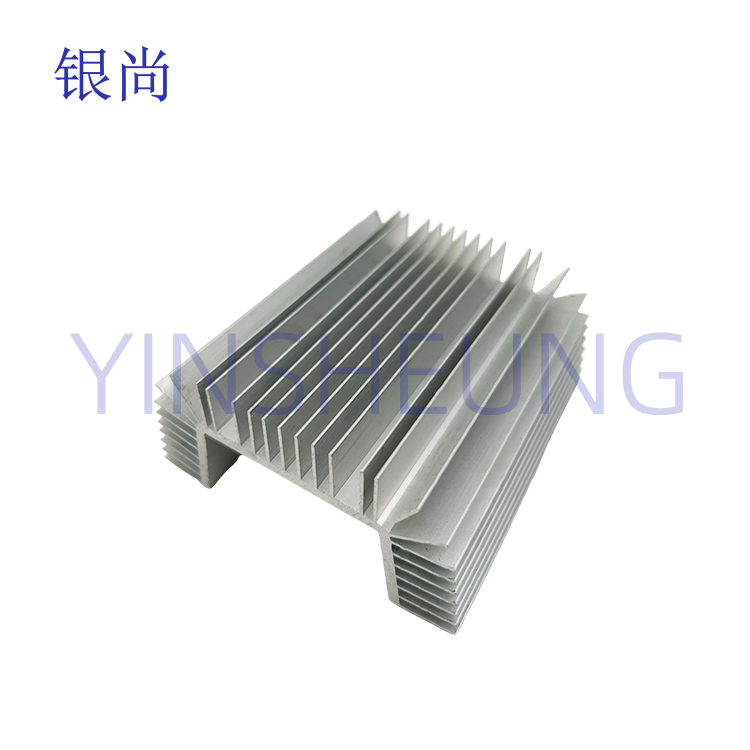

6063 aluminum alloy belongs to the Al Mg Si series alloy and has a wide range of applications, especially in the construction industry. It is the most promising alloy. Good corrosion resistance, excellent weldability, good cold workability, and moderate strength.

The main alloy elements are magnesium and silicon, which have excellent processing performance, excellent weldability, extrusion and electroplating properties, good corrosion resistance, toughness, easy polishing, coloring film, and excellent anodizing effect. They are typical extruded alloys. 6063 aluminum alloy profiles are widely used in building profiles, irrigation pipes, pipes, rods, and profiles for vehicles, platforms, furniture, elevators, fences, etc., due to their good plasticity, moderate heat treatment strength, good welding performance, and gorgeous surface color after anodizing treatment.

A low alloying Al Mg Si series high plasticity alloy. It has many valuable features: 1. Heat treatment strengthening, high impact toughness, and insensitivity to defects. 2. It has excellent thermoplastic properties and can be rapidly extruded into various profiles with complex structures, thin-walled and hollow sections, or forged into forgings with complex structures. It has a wide quenching temperature range and low quenching sensitivity. After extrusion and forging demolding, as long as the temperature is higher than the quenching temperature. It can be quenched by spraying water or penetrating water. Thin walled parts (6<3mm) can also be air quenched. 3. Excellent welding performance and corrosion resistance, with no tendency for stress corrosion cracking. Among heat treatable and reinforced aluminum alloys, Al Mg Si alloy is the only alloy that has not been found to exhibit stress corrosion cracking. 4. The surface after processing is very smooth and easy to anodize and stain. Its disadvantage is that if it is left at room temperature for a period of time after quenching and aged, it will have a negative impact on strength (parking effect)