How much do you know about anodized aluminum profile coating?

Yinsheung CNC Machining 13th Dec, 2023 Published in Foshan

Do you know about anodized aluminum profile coating?

Whatever it is natural anodizing, electrochemical, chemical anodized, alkaline anodizing, acidic oxidation, or oxidization, the composition of aluminum anodized film is the same, mainly composed of Al2O3.

The composition of this film can protect the aluminum substrate from further oxidation and corrosion, and will not rust like iron after years. People discovered this and started writing on this layer of film.

There are two main types of anodized coatings on aluminum alloys: barrier type anodized coatings and porous type anodized coatings

And what we can make use of is the porous anodizing film.

A porous anodized film consists of two parts

- a porous layer

- and a barrier layer.

A porous layer, as the name suggests, is a membrane layer with many small pores, and its pore radius is measured in micrometers. The barrier layer, located between the aluminum substrate and the porous layer, is porous and dense, isolating external air. It has the same structure as the barrier type anodized film, but cannot be understood as the barrier type anodized film.

What are its properties?

1. The porous anodized film has a two-layer structure, with the inner layer being high-purity aluminum oxide. It is a dense and thin glassy film with a thickness of about 0.01-0.05mm and high hardness; The outer layer is a water containing aluminum oxide (Al2O3 · H2O) film.

2. The anodized film is fixedly bonded to the substrate because it is generated from the substrate metal and forms a whole with the substrate metal.

3. The anodized film has many pores, which are cone-shaped capillaries with larger pore sizes from the inside out. Therefore, it has good adsorption capacity, easy to dye into various colors, and enhances decorative effects, strong adhesion with coatings, suitable for use as the bottom layer of coatings.

To improve corrosion resistance, sealing treatment should be carried out.

4. The anodized film is an insulator, and when the film thickness is 1 μm, the breakdown voltage is 25V; The resistivity of pure aluminum anodized film is 109 Ω/cm2.

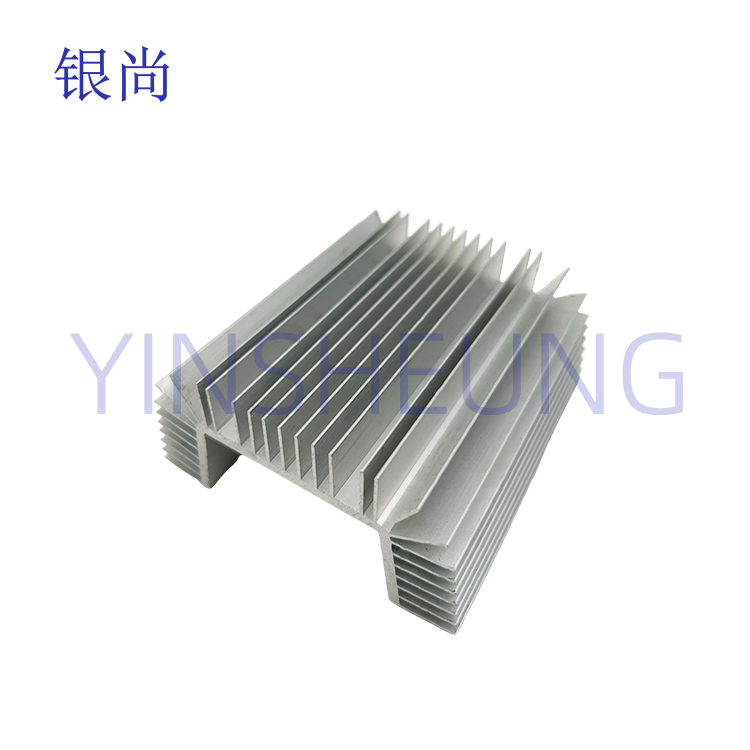

5. The anodized film has excellent heat resistance, with a heat resistance of up to 1500 ℃, and its thermal conductivity is lower than that of metals.

6. After anodizing treatment, the size of the aluminum profile increases slightly because the volume of aluminum anodizing is larger than that of original aluminum alloy.

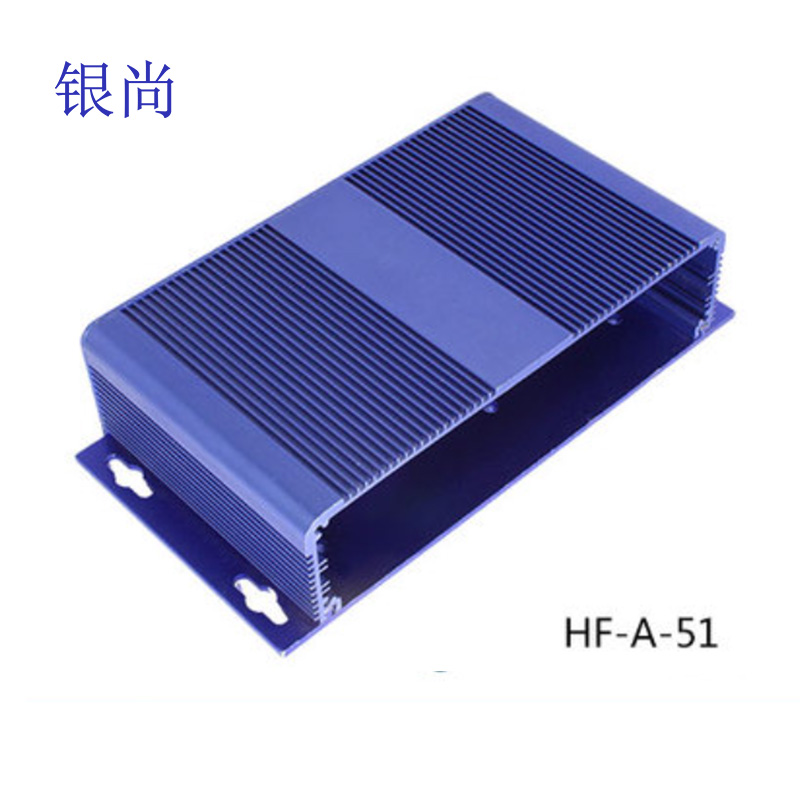

People began to pursue the practicality and visual appeal of aluminum alloys by utilizing the characteristics of aluminum oxide films. Dyeing with anodized film has become very common, and many of the colored casings of the phones we use, such as smart phones case, are made of aluminum alloy and anodized treatment.