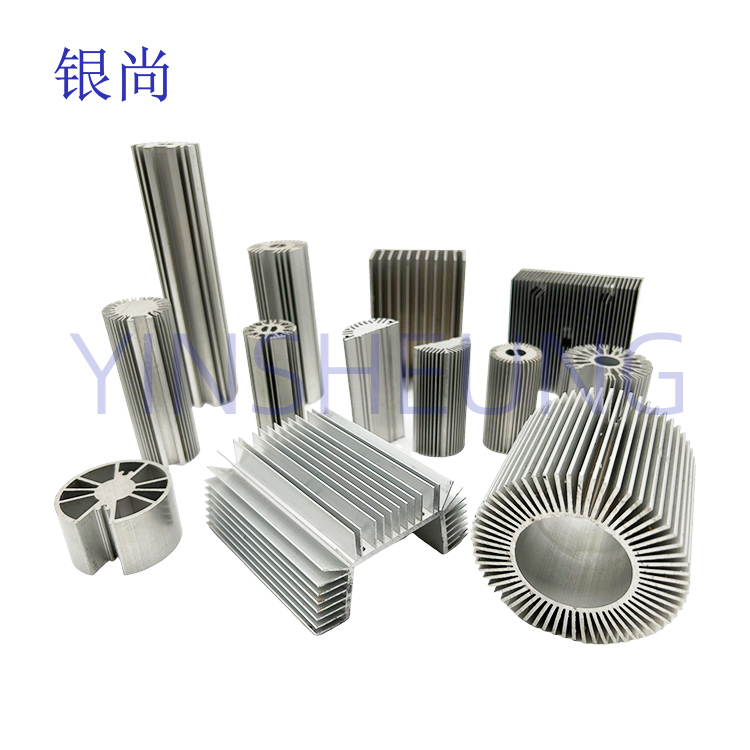

Aluminium Alloy Sections Profile

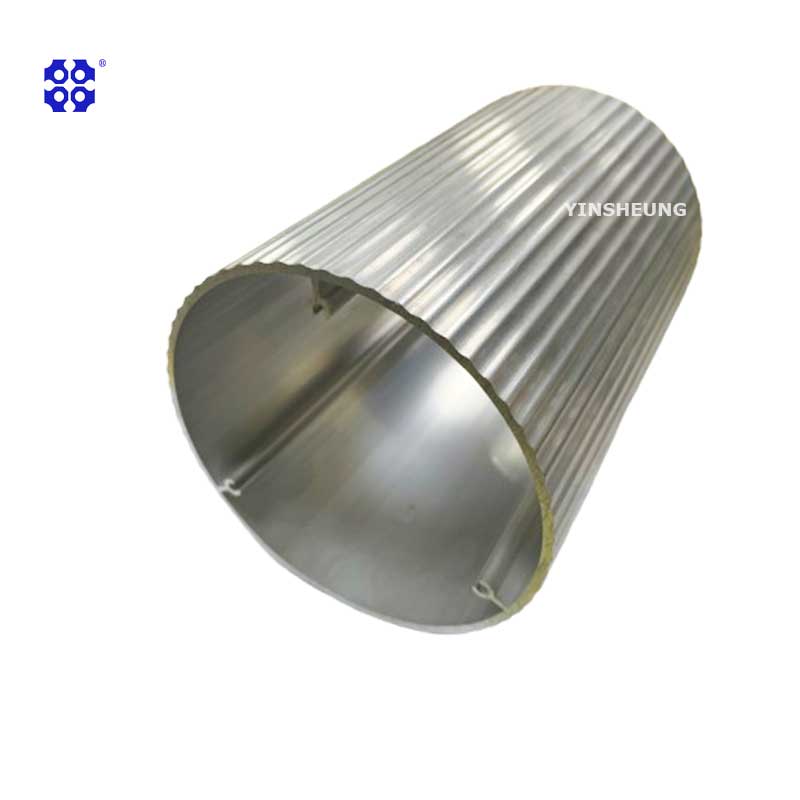

Aluminum is a lightweight, non-magnetic, silver-colored metal that can be formed into almost any shape. It can be rolled into thick plates for armored tanks or thin foil for wrappers. It can also be drawn into wire and made into cans.

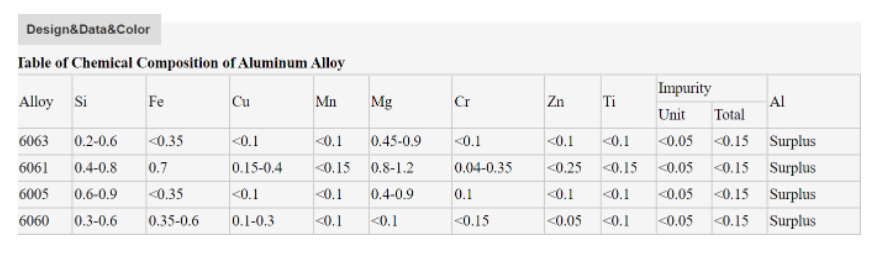

Pure aluminum is soft and has limited strength. Small amounts of elements such as copper, magnesium, and zinc are often added to increase strength.

Aluminum is a comparatively new industrial metal that has been produced in commercial quantities for just over 100 years.

Aluminum 6063

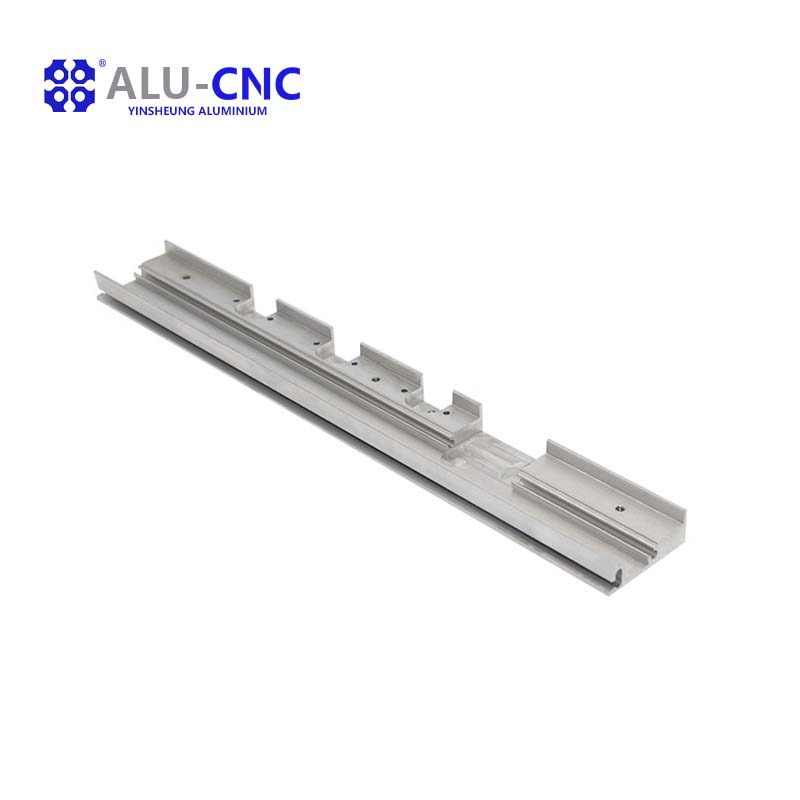

Aluminum is the most popular metal for CNC Machining, especially 6061 aluminum, because of its excellent strength-to-weight ratio, low cost, recyclability, and machinability. 3Q Machining offers precision machining with multiple aluminum alloys.

Aluminum properties:

Designers and engineers frequently choose aluminum and aluminum alloys for CNC machining and CNC milling parts. Makes sense. This all-purpose metal has been proven to offer:

- ·Easily machined

- ·High strength to weight ratio

- ·Hardness

- ·Excellent corrosion and chemical resistance

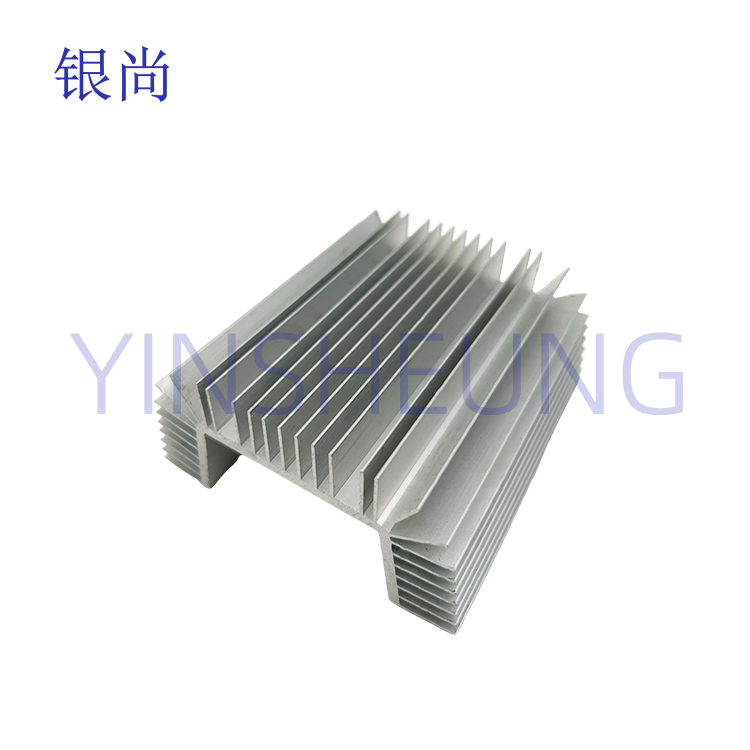

- ·Good Heat and electrical conductivity

- ·Overall versatility

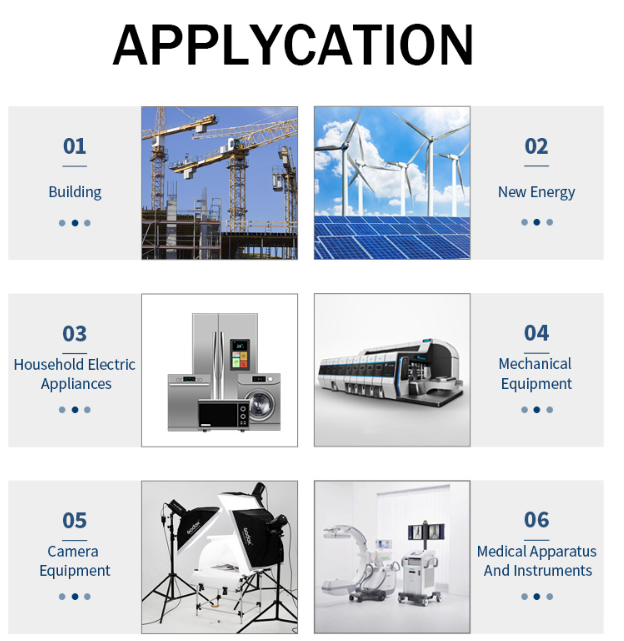

Machined Aluminum Applications

Aluminum parts can be found everywhere, in a range of industries, especially automotive, aerospace, industrial equipment and machinery, and consumer and computer electronics.

- ·Automotive parts (light-weighting provides high strength-to-weight ratio)

- ·Housing, brackets, and other components for aerospace use that must support heavy load capacities but be light weight

- ·Fixtures, calipers, and a variety of other parts for industrial equipment

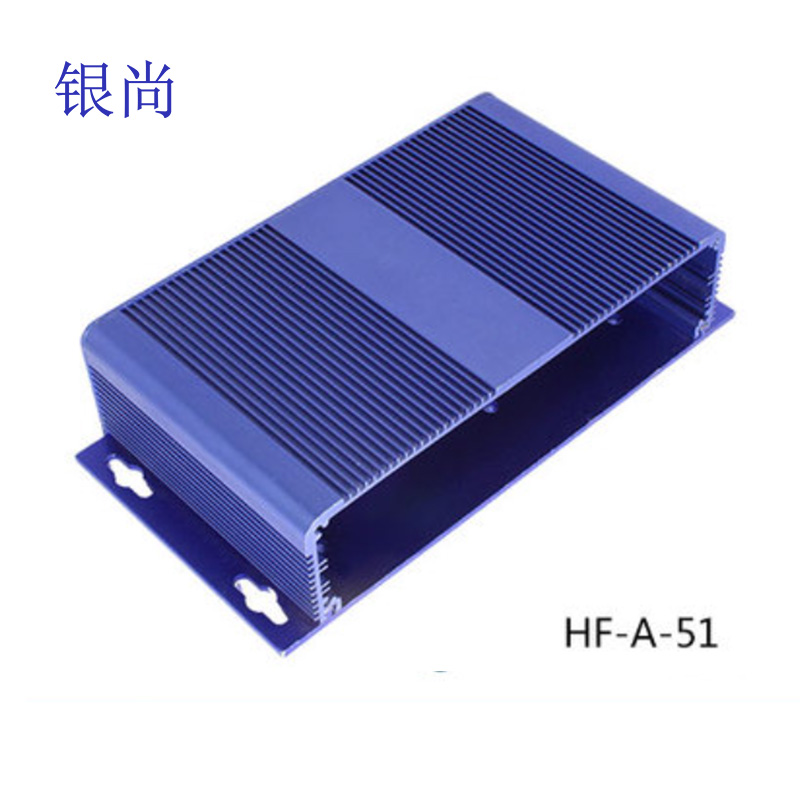

- ·Enclosures, panels, consoles, knobs, housing, and other applications for consumer and computer electronics